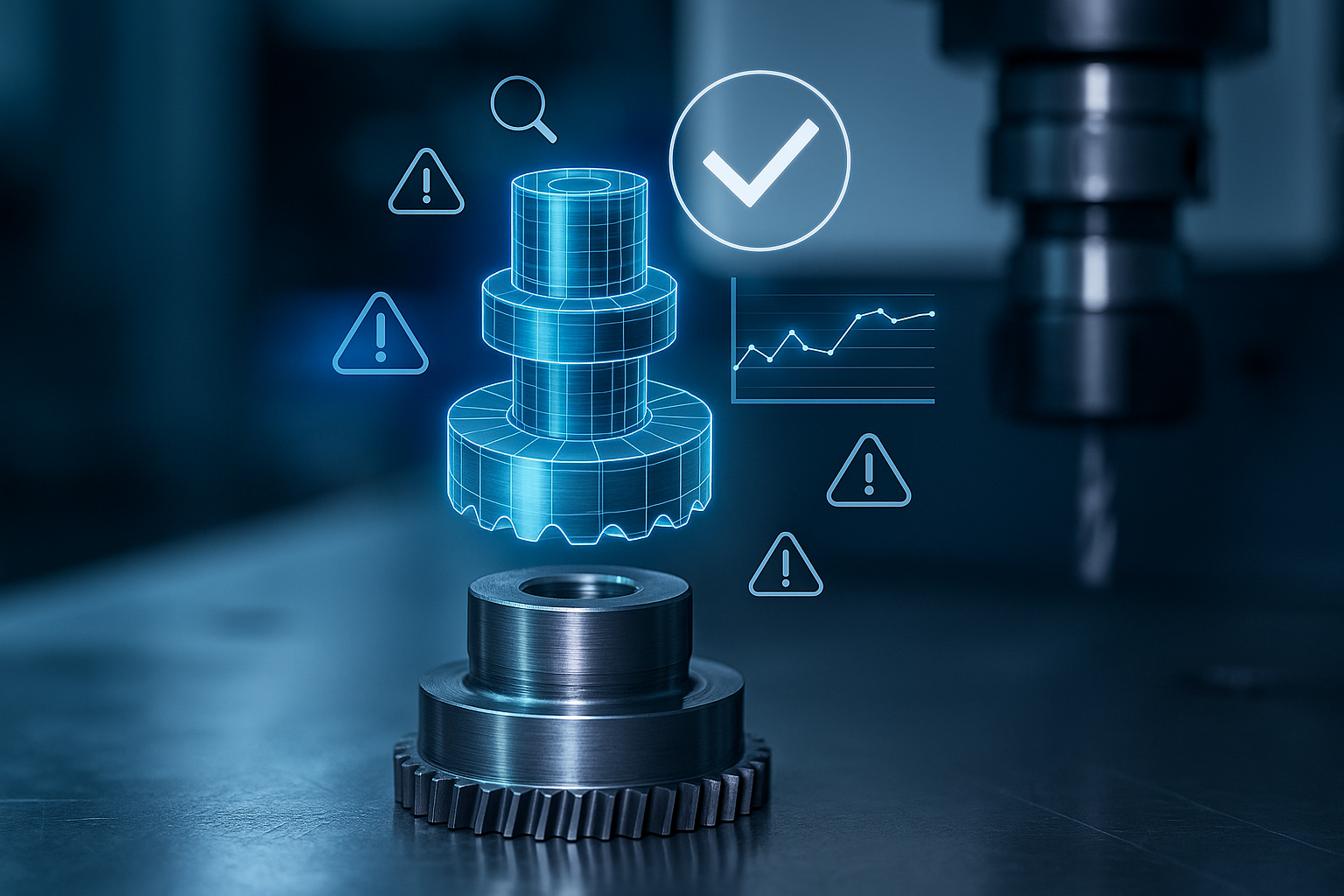

The Role of Digital Twins in Quality Control for Manufacturing

As Industry 4.0 continues to evolve, the adoption of digital twin technology is reshaping quality control (QC) in manufacturing. Digital twins provide a dynamic, data-driven virtual representation of physical products and processes, enabling manufacturers to achieve higher precision and reduce defects. This technology is crucial for machine shops aiming to enhance operational efficiency and maintain competitive advantage.

Why This Topic Matters for Machine Shops

The integration of digital twins into manufacturing processes is becoming increasingly vital as industries strive for zero-defect production. Machine shops can leverage this technology to move from traditional QC methods, which often rely on reactive measures, to a proactive approach that anticipates and mitigates potential issues before they occur. This shift not only improves product quality but also optimises resource utilisation and reduces waste.

How It Works

A digital twin is a real-time virtual model that mirrors a physical object or system. It integrates data from various sources, including sensors, manufacturing execution systems (MES), and metrology tools, to create a comprehensive view of the production environment. This allows for continuous monitoring and analysis of performance metrics, enabling manufacturers to detect deviations from desired specifications instantly.

Practical CNC Applications

Digital twins can be applied across various CNC machining processes. For instance, they can simulate different machining conditions to predict outcomes and optimise tool paths. This capability allows operators to test changes in real-time without halting production, thereby reducing downtime and improving overall efficiency. Additionally, digital twins can facilitate predictive maintenance by analysing wear patterns and operational data, ensuring that machines operate at peak performance.

Benefits & ROI

The implementation of digital twins in quality control offers several key benefits:

– Reduced Downtime: By predicting potential failures and enabling proactive maintenance, machine shops can minimise unplanned downtime.

– Lower Scrap Rates: Real-time monitoring allows for immediate corrective actions, reducing the amount of scrap produced.

– Extended Tool Life: Continuous analysis of tool wear can lead to better maintenance schedules, prolonging tool life and reducing costs.

– Enhanced Efficiency: Streamlined processes and reduced trial-and-error lead to faster production cycles and improved resource allocation.

The return on investment (ROI) from adopting digital twin technology can be substantial, with many manufacturers reporting significant cost savings and efficiency gains.

Getting Started

To successfully implement digital twins in a manufacturing environment, machine shops should consider the following checklist:

– Sensors: Invest in high-quality sensors to collect accurate data on machine performance and product quality.

– Data Integration: Ensure that data from various systems (CAD, CAM, MES) can be integrated into a unified digital twin.

– Skills Development: Train staff in data analysis and digital twin technology to maximise its potential.

– Software Solutions: Choose robust software that can handle real-time data processing and visualisation.

Risks & Limitations

Despite the advantages, there are challenges associated with the adoption of digital twins:

– Data Gaps: Incomplete or inaccurate data can lead to misleading insights, compromising the effectiveness of the digital twin.

– False Alarms: Over-reliance on automated systems may result in unnecessary interventions, disrupting production.

– Vendor Lock-in: Choosing proprietary solutions may limit flexibility and increase costs in the long term.

Addressing these risks requires careful planning and a clear understanding of the technology’s limitations.

Outlook for 2025+

As digital twin technology continues to advance, its role in quality control is expected to expand significantly. By 2025 and beyond, we can anticipate greater integration of digital twins throughout the entire product lifecycle, making them essential tools for real-time decision-making. This evolution will not only enhance quality assurance but also contribute to improved customer satisfaction through consistent product quality.

Key Takeaways

– Digital twins provide a real-time virtual model of manufacturing processes.

– They enable proactive quality control, reducing defects and downtime.

– Implementation requires investment in sensors, data integration, and staff training.

– Challenges include data accuracy, potential false alarms, and vendor lock-in.

– The future of quality control will increasingly rely on digital twin technology.

FAQ

- What is a digital twin?

- A digital twin is a real-time virtual representation of a physical product or process, integrating data from various sources for continuous monitoring and analysis.

- How can digital twins improve quality control?

- Digital twins enhance quality control by enabling real-time monitoring, predictive maintenance, and virtual testing, leading to reduced defects and improved efficiency.

- What challenges are associated with implementing digital twins?

- Challenges include data integration issues, the risk of false alarms, and potential vendor lock-in with proprietary solutions.

Original reporting/source: metrology.news

3 Comments