CloudNC has announced a major milestone for its flagship CAM automation solution. More than 1,000 machine shops across the globe are now using CAM Assist to accelerate CNC programming with artificial intelligence.

Since its launch in 2024, CAM Assist has been helping machinists overcome one of the industry’s biggest bottlenecks: the time and expertise required to convert CAD models into machining strategies and reliable toolpaths. By automating the most repetitive and time-consuming programming steps, the solution allows engineers to spend less time on setup and more time on higher-value work.

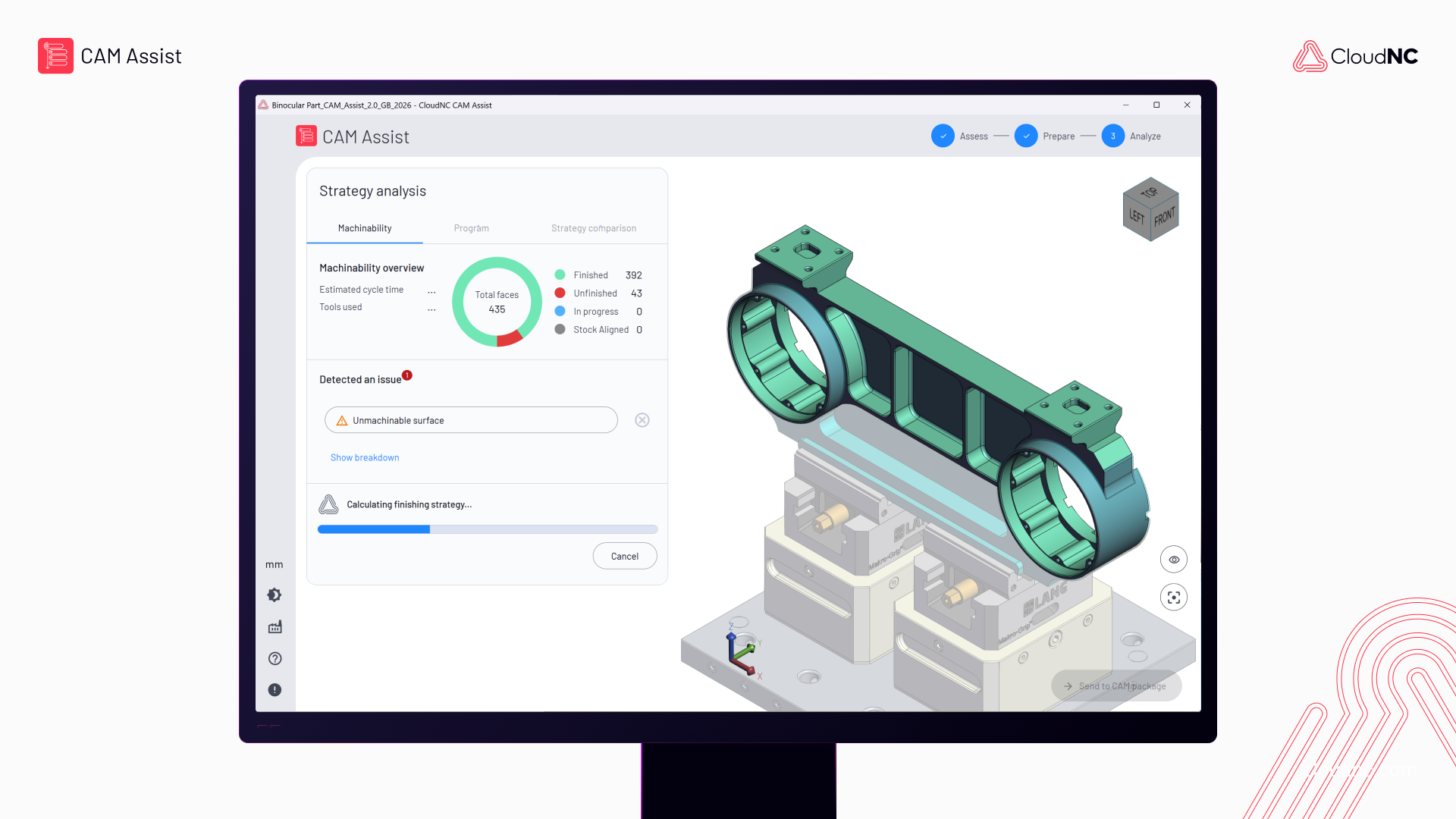

Now, CloudNC is rolling out CAM Assist 2.0, a significant upgrade that blends the speed of AI with greater transparency and human oversight. The result is a workflow that not only reduces programming time but also builds user confidence in every decision the AI makes.

AI and Human Expertise Combined

CAM Assist 2.0 introduces step-by-step guidance, enabling users to review and adjust strategies at each stage before they are finalised. Programmers can configure machines, materials, and tool assemblies in minutes, see AI-driven recommendations in context, and then approve or edit them before export. This “human-in-the-loop” design ensures that shop standards are never compromised while still saving hours on programming.

“AI and human expertise can work side by side,” explained Dr Andy Cheadle, CTO at CloudNC. “By letting machinists see – and influence – the AI’s decisions, CAM Assist 2.0 helps shops program faster and with greater confidence.”

For users, the benefits are immediate. Anthony Stephenson, prototype machinist at Avalanche Energy, commented: “CAM Assist automates the most time-consuming programming work in just a few clicks. The new 2.0 interface is clean and intuitive, making programming easier and faster—and helping us get more parts out the door.”

Key Features of CAM Assist 2.0

- One-click configuration: Intelligent defaults streamline setup so programming can begin within minutes.

- AI guidance at every step: Recommendations adapt to part geometry, machine limits, tools, and fixtures.

- Human-in-the-loop oversight: Every strategy can be reviewed, adjusted, and approved before committing.

- Seamless integration: Approved toolpaths are pushed directly back into Autodesk Fusion, Mastercam, or Siemens NX.

By combining AI speed with hands-on control, CloudNC is positioning CAM Assist as a practical tool for the modern shop floor. With machine, material, and tool data stored in the cloud, shops can also standardise output across teams, ensuring consistent results and reducing variation between programmers.

Impact on Manufacturing Productivity

The growth of CAM Assist reflects a wider trend in advanced manufacturing: using AI to address skills shortages and improve throughput. Machine shops are under increasing pressure to deliver parts faster, with fewer skilled programmers available. By embedding intelligence directly into the CAM workflow, CloudNC believes CAM Assist offers a scalable way for manufacturers to close that gap.

CloudNC, founded in 2015, continues to invest in AI solutions for manufacturing. Backed by leading investors including Atomico, Episode 1 Ventures, Autodesk, and Lockheed Martin, the company is headquartered in London with its own factory in Chelmsford. Its mission remains clear—to transform how parts are made by bringing automation and intelligence to every stage of CNC machining.

With CAM Assist 2.0 now available to all existing customers and further platform integrations on the horizon, CloudNC is set to play a central role in the future of AI-driven manufacturing.

For further information on CloudNC please visit:

One Comment