AI in UK manufacturing is reshaping how factories approach automation, productivity, workforce development and competitive performance. While investment in automation is expected to rise sharply during the next five years, the central challenge is not technology availability. The real task is adoption. Across OEMs and subcontractors, many report that the biggest obstacle is workforce capability. Technical skills and automation readiness decide whether automation and artificial intelligence deliver measurable returns.

This analysis explores how robotics, AI and advanced workholding provide practical, high value automation paths and why 1st MTA sees a major opportunity for UK industry.

Overview

With automation investment increasing, many UK manufacturers still struggle to unlock productivity. Workforce capability and technical skills remain the primary barriers to applying automation and AI. This overview outlines a pragmatic approach that focuses on high return systems such as workholding, flexible fixturing and bar feeding capability which often deliver gains faster than a full robotic deployment.

Topics covered:

- When a robot is useful and when it may not be the most effective choice

- Why specialised automation systems such as advanced workholding can deliver higher value in many cases

- Strategies to reduce the UK automation skills gap

- The convergence of AI and automation

- Career opportunities in UK engineering and manufacturing

Key facts affecting the UK

- The UK factory automation and industrial control systems market is forecast to grow at more than 10 percent CAGR between 2025 and 2030 according to Mordor Intelligence.

- UK manufacturing robot density stands at around 111 robots for every 10,000 employees.

- Engineering and technology roles account for around 19 percent of all UK employment, equal to approximately 6.4 million people, and 25 percent of all job advertisements.

- Nearly half of UK manufacturers say lack of technical skills is a major automation barrier.

1st MTA views this as both a challenge and a commercial opportunity. By providing automation ready workholding systems and modular fixturing, the business supports UK factories as they move from manual approaches to higher levels of automation and prepares them for smart manufacturing environments.

Robots Are Not Always the First Automation Answer

Robots are often viewed as the definition of automation. In many UK environments, robots are powerful but may not be the most practical first step. Reasons include:

- Many production tasks still require human insight

- High capital cost and uncertain ROI

- Programming and integration effort

- Skills needed to maintain and manage robotic cells

- Limited adaptability when part variation is high

- Simple loading or bar handling can be automated more effectively using dedicated systems

In the UK context, robot deployment numbers remain relatively low. Data shows that many manufacturers operate without robotics even though productivity requirements are rising.

A UK automotive supplier invested in a robot for part loading on a variable production line. The system suffered from long idle periods due to changeovers and programming requirements. It was later replaced by a modular bar feeder and smart workholding which delivered higher uptime and simpler changeover.

1st MTA offers automation compatible workholding and modular fixtures that help manufacturers build toward robotics in a structured way.

Workholding and Automation. The Foundation for Higher Throughput

Increasing the number of components under the spindle is one of the fastest ways to unlock productivity. High density workholding reduces manual loading, supports lights out machining, increases repeatability and enables smoother integration with automation later.

1st MTA solutions include:

- Chick Qwik Lok vices for rapid part changeover

- Chick Multi Loks for clamping multiple components

- Sinco zero point clamping for fast fixture changes

- Automated loading and pallet systems for unattended production

The objective is to reduce machine idle time, increase cutting hours and build an automation platform inside the machining envelope.

UK Market Context

- UK factory automation market is projected to rise from £12.3 billion in 2025 to £20.3 billion by 2030 with CAGR above 10 percent.

- UK industrial automation revenues reached £8.89 billion in 2024 and are expected to reach £14.82 billion by 2030.

- Automation benefits include higher productivity, better product quality and lower labour dependency.

A recent UK precision engineering project that implemented multi part fixturing increased unattended production by 30 percent and improved throughput by 22 percent.

Closing the Skills Gap

- Around 6.4 million people work in engineering and technology roles

- Engineering and tech jobs represent approximately 25 percent of all UK job adverts

- The UK faces a projected shortage of engineers by 2030

- Nearly half of manufacturers say skills are a barrier to automation

Priorities include training, reskilling, STEM participation, workforce diversity, industry collaboration and developing system integration skills. Automation should be approached as augmentation that enables higher level work rather than replacement.

A UK manufacturer that partnered on automation training cut operator downtime by 18 percent and enabled additional unattended shifts.

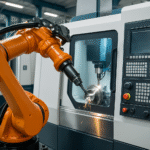

AI and Automation. The Convergence

Automation handles repetitive work and AI enables learning, pattern recognition and adaptive responses. Combined, these support predictive maintenance, proactive decision making, fault prevention and improved product quality. In UK manufacturing, AI driven inspection and robotics integration are reducing defects and boosting efficiency.

A case example in UK electronics achieved a 45 percent reduction in defects and a 35 percent decrease in idle time using machine vision AI linked to robotic sorting and pallet systems, supported by automation compatible workholding.

Career Outlook in UK Manufacturing

Engineering roles remain essential across automation, robotics integration, data driven operations, advanced manufacturing and emerging sectors such as green manufacturing and aerospace. Studies expect large numbers of skilled roles to open through retirement and sector expansion. Engineering offers high employability, global mobility and long term security. New digital pathways, apprenticeships and degree routes continue to grow.

Key Takeaways

- UK manufacturing needs to accelerate automation and AI adoption to remain competitive

- Robots are valuable although not always the first practical automation step

- Workholding, modular fixturing and bar feeding offer faster ROI in many plants

- The UK faces a significant engineering skills gap

- AI and automation are creating new career paths rather than eliminating roles

During the next decade, UK manufacturing has an opportunity to unlock significant productivity if it integrates automation carefully, develops workforce capabilities and chooses scalable technologies. 1st MTA solutions are positioned to support this transition through workholding innovation and automation compatible systems that prepare the machining environment for more advanced automation during the years ahead.

Frequently Asked Questions

What is AI in UK manufacturing

AI in UK manufacturing refers to automation, robotics, and smart inspection used in British production environments.

Is robotics required for automation

Not always. Advanced workholding and bar feeding often deliver faster ROI.

What is the main barrier

Skills, integration capability and workforce readiness remain the main obstacles.

Further reading:

For More information on 1st MTA please visit their site www.1mta.com