AI in sheet metal automation is advancing at a rapid pace as fabricators upgrade bending, laser cutting, and material handling with adaptive intelligence, real time monitoring, and software guided precision. AI in sheet metal automation continues to influence production strategies as more manufacturers look for stable and scalable digital workflows. December reporting across industry publications confirms that automation suppliers and sheet metal shops are entering a new phase of digital capability driven by vision systems, intelligent cutting parameters, and integrated workcells. This roundup brings together the most important December developments shaping smart bending and laser cutting.

AI Vision Systems Lead December Adoption Trends

December coverage in The Fabricator highlights a clear shift toward AI powered vision and inspection technology in high mix sheet metal environments. These systems identify part type, confirm orientation, detect defects, and guide robots through sorting and handling tasks directly after laser cutting.

Key December gains include:

• Orientation detection that improves press brake loading

• Fast defect spotting during unload

• Automated quality checks between cutting and bending

• More stable flow in flexible batch production

These upgrades strengthen the role of AI in sheet metal automation by reducing manual inspection and supporting consistent precision across small and large production runs.

Smart Bending and Laser Cutting Receive December Software Upgrades

Trade outlets report that suppliers are releasing more adaptive bending and intelligent cutting controls. These tools improve bend accuracy, monitor springback, adjust laser cutting speed, and tune focus height based on real time material feedback.

December updates show:

• Software guided bending cycles to reduce setup time

• Laser optimisation that improves cut quality on steel and aluminium

• Automated program selection for repeated jobs

• Digital work instructions that reduce operator skill barriers

These enhancements match MTN categories such as AI in CNC and AI in Sheet Metal where optimisation software continues to outrank mechanical changes in impact.

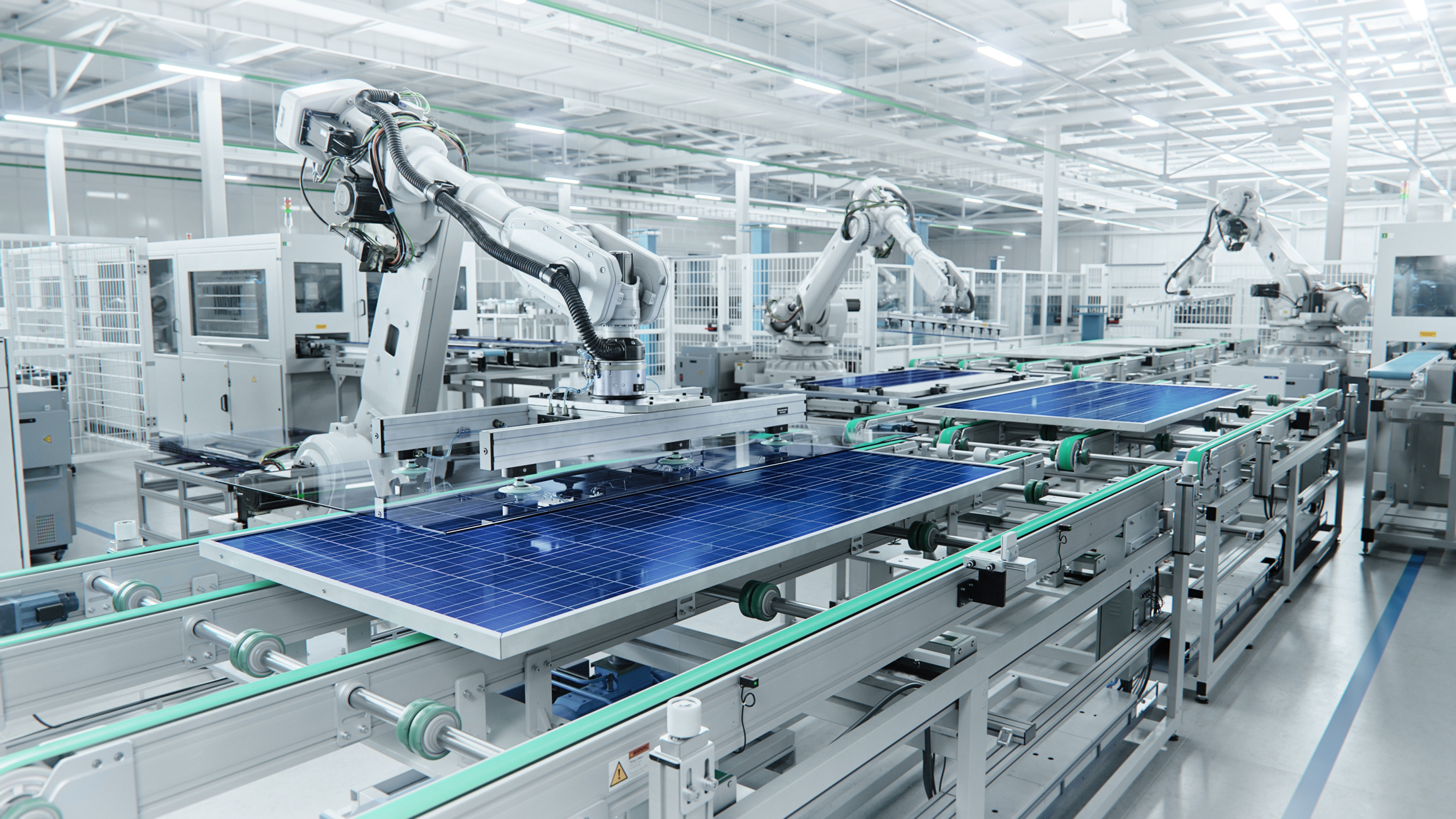

AI Driven Material Handling Expands Across Fabrication Shops

AI driven gripping and robotic handling systems received strong attention in December market commentary. These upgrades help production teams move parts between laser cutting, deburring, and bending cells without stoppages.

This month’s advantages include:

• Faster transitions between part families

• Reliable handling of thin, reflective, or irregular materials

• Continuous workflow with fewer manual lifts

• More predictable cycle times across shifts

Material handling remains a major return on investment area for shops adopting AI in sheet metal automation because it stabilises overall machine utilisation.

December Manufacturing Events Highlight Highly Connected Workcells

Ongoing December updates in global sheet metal production show strong growth in automation and digital workflows, highlighted by MetalForming Magazine. European sheet metal exhibitions held in early December reported new demonstrations featuring fully integrated cutting and bending lines. These installations showcased:

• Robotic press brake loading with AI monitored angle correction

• Automated tool changes and bend sequence optimisation

• Laser units with dynamic power control

• Digital twin simulations covering entire production sequences

These connected systems reduce work in process, shorten lead times, and help teams validate jobs before cutting begins. This aligns with the direction of Industry 4.0 across fabrication.

Integrated Automation Headlines Point to 2026 Momentum

December news from MetalForming Magazine and related outlets indicate strong interest in unified automation built around data, predictive software, and adaptive controls.

Reported benefits include:

• Higher press brake utilisation

• Lower scrap due to live cutting parameter tuning

• Faster job verification

• Smoother scheduling supported by machine data analytics

These trends show that AI in sheet metal automation is becoming central to strategic planning for 2026 as fabricators prioritise reliability and throughput.

Key Takeaways for December

With steady adoption visible across exhibitions and December news reports, AI in sheet metal automation is set to guide strategic investment decisions for 2026.

• Vision systems are rapidly spreading across bending and laser cutting workcells

• AI guided bending and cutting software is replacing manual adjustments

• Material handling intelligence is increasing transfer speed and stability

• Connected production lines showcased in December reveal the future direction of metal fabrication

• AI is now delivering measurable value in accuracy, scrap reduction, and cycle time

FAQ

What is the main benefit of AI in sheet metal automation?

It increases process stability, reduces rework, and improves accuracy in bending and laser cutting.

How does AI improve laser cutting?

It adjusts power, speed, and focus during cutting to improve edge quality and consistency.

Why is AI vision important for fabrication?

It identifies defects, confirms orientation, and supports robotic loading and unloading.

Which sheet metal processes are adopting AI fastest?

Laser cutting, bending, and robotic handling are the leading use cases in December reports.

Do AI systems reduce cycle time?

Yes, they streamline movement, adjust parameters without downtime, and improve program readiness.