The information in this article is based on details provided by DFKI, who have shared new insights into their latest research on an autonomous welding robot designed for maritime infrastructure maintenance. Their work highlights how AI driven sensing, underwater manipulation, and continuous welding techniques are coming together to create a safer and more efficient approach to subsea repair. This project offers a clear view of how advanced robotics are beginning to reshape some of the most demanding tasks in the maritime sector.

A groundbreaking underwater robotic system has been developed that can autonomously execute welding operations beneath the waves, offering a transformative solution for the maritime industry’s critical infrastructure challenges. The MARIOW project (Maritime AI-Guided & Remote Operated Welding) brings together artificial intelligence, advanced sensing, and modular robotics to shift hazardous, labour-intensive welding tasks away from human divers and toward reliable automation.

Next-Generation Underwater Welding

Traditional underwater welding relies on skilled industrial divers working in demanding environments where visibility is limited, currents are strong, and safety risks are high. Demand for maintenance far outstrips the available workforce for these tasks. The MARIOW system directly addresses this gap by integrating AI and robotics into the maintenance workflow so that the robot can identify, plan, and execute welds with precision.

At the heart of the system is a robust modular underwater manipulator engineered for depths of up to 6,000 metres. This manipulator offers a two-metre reach and can be reconfigured for different maritime repair scenarios, from port infrastructure to offshore platforms, enabling controlled welding movements in conditions that would challenge even expert human divers.

AI-Driven Seam Detection and Path Planning

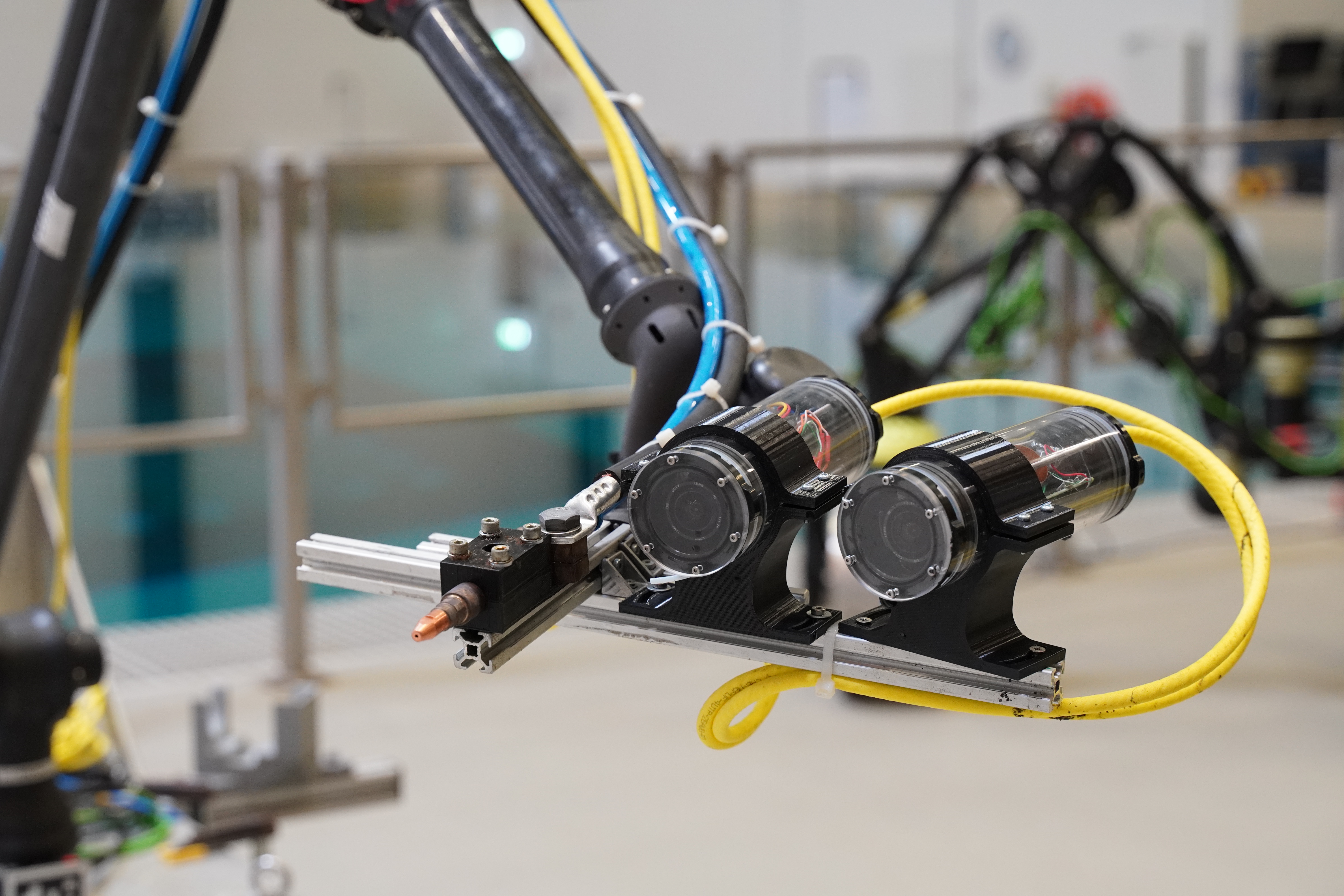

One of the most novel aspects of the MARIOW robot is its ability to autonomously determine where and how to weld. A stereo camera system mounted at the welding torch captures high-resolution imagery in real time. AI models, developed and trained by partners in the project, process these images to detect weld seams and calculate their start and end points. Based on this analysis, the system generates an optimized trajectory for the robot to follow. This capability means the robot can make intelligent decisions underwater without constant human input.

Innovative Continuous Welding Process

A breakthrough enabling true automation is the adoption of an underwater flux-cored arc welding (UW-FCAW) process. This method replaces traditional stick electrodes—requiring frequent manual changes—with a continuous wire feed. The uninterrupted material stream is essential for consistent, controlled welds, making automation feasible for all but the most complex subsea environments.

Demonstrating Practical Capability

In a final project demonstration at DFKI’s underwater test facility in Bremen, the complete suite of technologies was integrated and tested. The robot successfully identified weld paths using its AI systems, planned motion paths, and executed submerged flux-cored arc welding operations. Project lead Christian Koch described the results as proof that automated underwater welding is viable and holds significant promise for maritime maintenance applications. Future work will focus on refining seam quality, adapting to dynamic harbour conditions, and integrating systems such as laser slag removal to further enhance performance.

Implications for Maritime Industries

By reducing dependence on human divers for repetitive and dangerous welding tasks, this autonomous solution has the potential to dramatically improve safety, efficiency and long-term sustainability of maritime infrastructure maintenance. As ports, offshore energy installations, and coastal defence structures age, such robotic systems are poised to play a central role in keeping these assets operational with lower risk and higher precision.