Quality is a competitive edge in fabrication. Missed defects can trigger expensive rework, warranty claims, and brand damage. That’s why manufacturers are increasingly embracing AI cobot quality inspection – a combination of collaborative robots (cobots), computer vision, and machine learning designed to spot problems earlier and with greater consistency.

Unlike traditional automation, vision-guided cobots can be deployed flexibly across sheet metal fabrication, CNC machining, and final assembly lines. Their ability to adapt to changing part geometries, production volumes, and inspection criteria makes them especially valuable in high-mix, low-volume environments where conventional inspection systems struggle.

Beyond consistency, cobots also bring scalability and traceability – allowing inspection data to flow directly into enterprise systems, creating a digital thread that connects quality control with production, compliance, and customer reporting. This adaptability positions them not just as inspection tools, but as strategic assets for smarter factories.

Why AI Cobot Quality Inspection Is Different

Traditional inspection relies on human judgment, which – even in highly trained teams – varies across shifts. By contrast, AI-enabled cobots provide:

- Micron-level precision in weld, cut, or surface inspection.

- Scalable quality control for both high-volume and small-batch runs.

- Digital traceability that links every part to inspection records.

- Safer operations, as cobots handle repetitive visual checks while operators focus on complex tasks.

👉 Related read: AI in Sheet Metal to see how AI-driven weld inspection is reshaping fabrication lines.

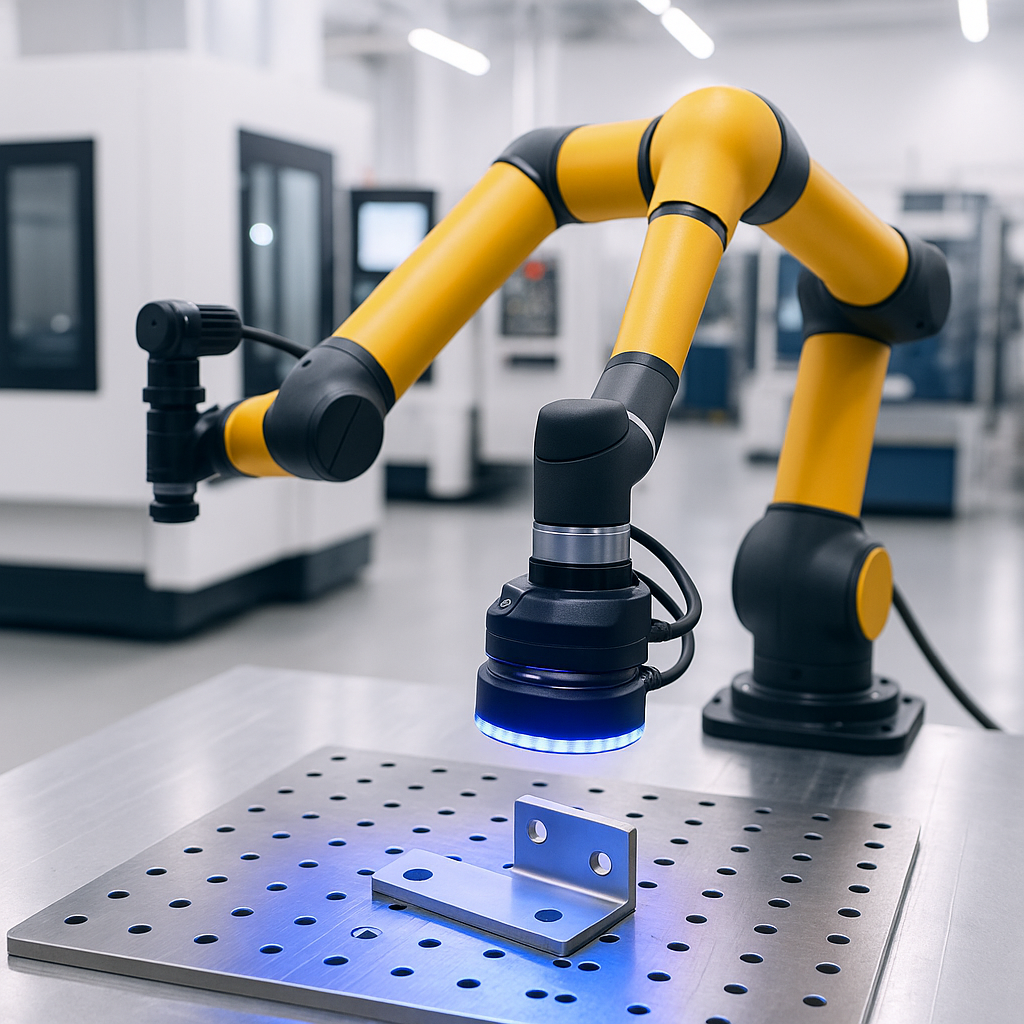

How Vision-Guided Cobots Work

The technology stack powering AI cobot quality inspection typically includes:

- Machine vision cameras – capturing weld seams, bend angles, or machined surfaces.

- AI algorithms – trained to detect cracks, porosity, or dimensional deviations.

- Collaborative arms – flexible enough to reposition sensors around complex geometries.

Unlike rigid inspection stations, cobots can be reprogrammed on the fly – ideal for plants producing diverse parts.

👉 Learn more about robotics integration in our Robotics hub.

Real-World Applications in Fabrication Plants

Manufacturers are already applying vision-guided cobots in:

- Weld inspection for sheet metal assemblies (detecting incomplete fusion and porosity).

- Dimensional checks in CNC machining (verifying tolerances against CAD).

- Surface finish monitoring (flagging dents, scratches, or paint inconsistencies).

- Inline 100% inspection (embedding cobots directly into production flow).

For example, automotive suppliers are using cobots to inspect spot welds in real time, feeding results directly into their manufacturing execution systems (MES).

The Business Case: Cost, Scrap, and Customer Confidence

AI cobot quality inspection goes beyond catching defects. The measurable benefits include:

- Scrap reduction by detecting flaws earlier in the line.

- Lower warranty exposure by keeping defective parts from reaching customers.

- Faster compliance reporting with digital inspection logs.

- Enhanced customer confidence, especially in aerospace and medical markets.

According to McKinsey, AI-enabled quality control can cut defect detection costs by 50% in some advanced manufacturing environments.

Challenges and Best Practices

Rolling out AI cobot inspection isn’t plug-and-play. Key considerations include:

- Data quality: AI models require accurate defect libraries and training data.

- Integration: Inspection data should flow into ERP/MES systems for a closed loop.

- Operator training: Workers need confidence that cobots support, not replace, their expertise.

- Standardisation: Plants must set clear defect thresholds to avoid unnecessary rejections.

👉 Related resource: AI in CNC for insights into how machine shops are linking inspection data with adaptive control.

What’s Next for AI Cobot Quality Inspection?

The next wave is self-learning cobots capable of continuous improvement. By analyzing live production data, these systems will move from simply detecting defects to predicting them – closing the gap between inspection and process control, and even suggesting corrective adjustments in real time.

For fabrication plants under pressure to deliver zero-defect manufacturing, AI cobot quality inspection is no longer just a technology trend. It is becoming a new baseline for competitiveness, a core element of smart manufacturing strategies that align quality, efficiency, and customer trust.