AI in Italian manufacturing is entering a transition phase at the end of 2025. While larger automation leaders and robotics suppliers continue to ramp up activity, the wider market remains mixed. Many Italian machine builders, welding integrators, and CNC suppliers are moving forward with artificial intelligence, but smaller workshops are still cautious due to cost pressure, integration complexity, and uncertainty about long term return on investment. Recent industry data shows that AI adoption in Italy remains uneven and heavily concentrated among companies that already have strong digital foundations.

Italy remains one of Europe’s most important machine tool producers and a global exporter of industrial expertise. Regions including Lombardy, Emilia Romagna, Piedmont, and Veneto have strong manufacturing clusters and are experimenting with industrial robotics, advanced quality inspection, and predictive analytics. At the same time, Italy experienced a difficult 2024 for machine tools according to national industry figures, and recovery through 2025 has been slower than expected. This economic context shapes the pace of AI rollout. Heavy investment cycles take longer, and many companies are prioritising efficiency projects with fast payback.

Why AI in Italian manufacturing is moving from pilots to selective scale up

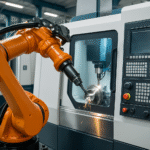

Large factories with export-focused business models are adopting AI technology for CNC, robotics, and laser systems. Typical use cases include predictive maintenance, intelligent process control, automated welding, and integrated inspection. The main driver is operational efficiency at a time when Italian manufacturers face energy costs, labour shortages, and rising competition from global automation suppliers.

Many factories report interest in AI assisted programming for CNC machines and multi process lines. Adaptive automation can reduce changeover times while supporting high mix production, which is common across Italian machining sectors. Early results indicate promising improvements in consistency and cycle times, although benefits depend on integration quality.

AI in sheet metal and welding is gaining traction where labour shortages are strongest

Italian manufacturers in sheet metal, automotive and heavy fabrication are investing in intelligent welding systems. AI driven seam tracking and machine vision inspection are helping companies stabilise quality and handle mixed part production. Welding cells with real time feedback loops and heat management are gradually spreading across large fabrication plants.

Robotic bending and smart laser systems are also expanding. Some Italian suppliers have introduced vision guided bending processes and automated setup features. These are practical technologies that solve immediate problems, which fits the cautious spending climate in Italy during 2024 and 2025.

Italian companies to monitor going into 2026

• Comau continues to combine robotics with advanced automation projects in automotive and industrial applications

• Prima Industrie works on laser systems, digital machine monitoring, and deeper process optimisation for metal manufacturers

• CMS and Brembana explore automation for composite and precision manufacturing

• Hexagon Italy develops inspection and metrology systems with advanced analytics

Adoption barriers are slowing broad rollout

ISTAT recently reported that only a small proportion of Italian companies currently use AI. This shows that adoption is still far from universal. Many Italian SMEs depend on manual processes and experienced operators. Digital skills remain limited, and regional differences across the country influence readiness.

Retraining, skills development, and clearer ROI cases will be essential for wider adoption. Retrofit solutions for older machines are helping companies modernise incrementally. Retrofit AI allows companies to upgrade legacy CNC equipment without immediate capital expenditure, which is a practical path during uncertain market conditions.

Government support through industry innovation funds and European digitalisation programmes is expected to influence adoption levels in 2026, including Industry 5.0 initiatives and regional manufacturing programs focused on sustainability and productivity.

Looking toward 2026

The outlook for AI in Italian manufacturing remains positive, but acceleration will probably be selective. Large manufacturers and robotics focused industries are moving ahead. Smaller factories are advancing more cautiously and often rely on incremental upgrades rather than full transformation. This is likely to continue through 2026 as Italian machine builders recover from a difficult period in 2024 and early 2025.

The next phase of industrial AI in Italy will be driven by practical applications that solve immediate shop floor challenges. Predictive maintenance, AI enabled quality inspection, CNC optimisation, and robotic welding will be the main areas of interest. Companies that demonstrate measurable improvements and short payback periods are likely to lead adoption in 2026.

FAQ about AI in Italian manufacturing

What is the current state of AI in Italian manufacturing in 2025

AI in Italian manufacturing is progressing but adoption is uneven. Larger companies and robotics focused factories are moving ahead faster than small workshops that require clearer ROI and integration support.

Why is AI in Italian manufacturing important for 2026

AI in Italian manufacturing is important because factories are under pressure from labour shortages, energy costs, and international competition. Practical AI for CNC, welding, and predictive maintenance can deliver measurable productivity improvements.

Which sectors are adopting AI in Italian manufacturing first

Sectors that use robotics, CNC machining, sheet metal, and welding are adopting AI first because these areas already have automation infrastructure and benefit directly from better process control and inspection.