AI in machine tools is moving fast this week, with new breakthroughs across CNC automation, robotic inspection, hybrid machining, and next-generation software shaping how factories operate. Fast, digestible updates on how AI and automation are reshaping CNC machining, sheet-metal production, and industrial inspection.

5 Big Updates This Week in AI in Machine Tools:

1. Forgis Raises €3.8M to Make Legacy Industrial Machines “Autonomous”

A big move in Europe this week as Forgis, a Swiss industrial-software startup, raised €3.8 million to retrofit legacy machines with intelligent automation.

Their platform plugs into existing CNCs, forming presses, weld cells and other production equipment to make them self-optimising, collaborative, and AI-assisted without expensive hardware upgrades.

Performance gains from early pilots:

- 60% reduction in machine-configuration time

- 30% reduction in downtime

- 20% increase in throughput

Why this matters:

This directly hits the pain point of small and mid-size manufacturers unable to buy brand-new AI-enabled equipment. Forgis shows how “software-first automation” can give older machine fleets the intelligence of next-generation systems.

AI in machine tools continues to evolve quickly, influencing everything from CNC automation to smart inspection and edge AI workloads.

2. Creaform Launches CUBE-R M Series for Automated 3D Inspection

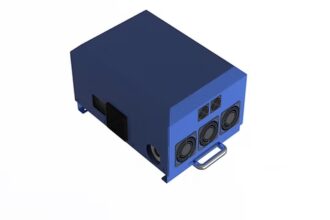

Creaform has unveiled the new CUBE-R M Series – a fully automated dimensional-inspection cell designed for high-volume metal manufacturing.

Built for sheet-metal, castings, weldments, and larger assemblies, it includes:

- Intelligent 3D scanning

- Pre-programmed inspection cycles

- Configurations supporting parts up to 4 metres

Why this matters:

With more fabricators investing in AI-driven inspection, the CUBE-R M Series brings a turnkey solution for reducing scrap, catching defects earlier, and moving past manual measurement bottlenecks. A recent analysis from TechCrunch highlights similar AI adoption trends across manufacturing.

Related read → Robot Vision Gets Smarter: AI Cameras in Inspection Lines

3. Rockwell Automation & NVIDIA Bring Generative AI to the Factory Edge

A major collaboration this week: Rockwell Automation is integrating NVIDIA Nemotron Nano into its industrial platform, enabling generative AI to run directly at the factory edge.

This allows factories-including CNC, laser-cutting, welding and assembly lines-to run AI without needing cloud connectivity.

Key features:

- Offline, air-gapped AI for sensitive production environments

- Natural-language work guidance

- Automated troubleshooting and workflow optimisation

- AI assistants for operators and maintenance teams

Why this matters:

Edge-native generative AI is a breakthrough for metal manufacturers who need ultra-low latency and strict data sovereignty.

This trend proves that AI in machine tools is no longer optional — it’s becoming a standard requirement for competitive machining operations.

You may also like → Edge AI in Metal Factories: Why Local Processing Is Beating the Cloud

4. HSG Laser Unveils Ultra-High-Power Smart Cutting Systems

At SMTECH 2025, HSG Laser showcased a new range of smart sheet-metal and tube-cutting solutions, including machines up to 60 kW and automated handling for heavy tube sections.

Highlights:

- Auto loading/unloading modules

- Smart thickness detection

- AI-driven cutting-path optimisation

- Enhanced energy-efficiency controls

Why this matters:

Metal fabricators continue pushing toward autonomous cutting cells, and HSG’s new line reinforces the shift to high-power lasers paired with intelligent automation.

Explore more → AI-Driven Sheet-Metal Nesting: Cutting Scrap and Carbon

5. Europe’s Multi-Axis Machining Market Set for Strong Growth

A new report forecasts Europe’s multi-axis machining centres market (4-axis, 5-axis, 7-axis) growing from USD 6.8 billion in 2025 to USD 11.9 billion by 2035.

Key growth drivers:

- Accelerating factory automation

- Higher precision requirements

- Digitalised machining environments

- Reshoring into Western Europe

Why this matters:

Shops planning investments in 2025–2026 will see growing demand for intelligent multi-axis machines, especially where automation and smart machining are becoming standard.

Shops investing early in AI in machine tools are already reporting better throughput, lower scrap, and more stable production cycles.

See → Conversational Programming: The Rise of Chat-Driven CNC

Final Thoughts for This Week

AI in machine tools is moving at full speed-not only through new robots and CNCs, but through intelligent overlays, edge-based generative AI, and smart inspection. The machine-tool landscape is clearly shifting from hardware-only to hardware + intelligence, and manufacturers adopting these technologies early will gain real operational advantage.

Manufacturers across Europe and the US are now evaluating how quickly they can integrate these AI-driven solutions into their CNC, sheet-metal, and welding environments. The appetite for smarter, more connected machines continues to rise. Manufacturers adopting AI in machine tools are now seeing clear gains in accuracy, speed, and production reliability.

MachineToolNews.ai on LinkedIn

One Comment