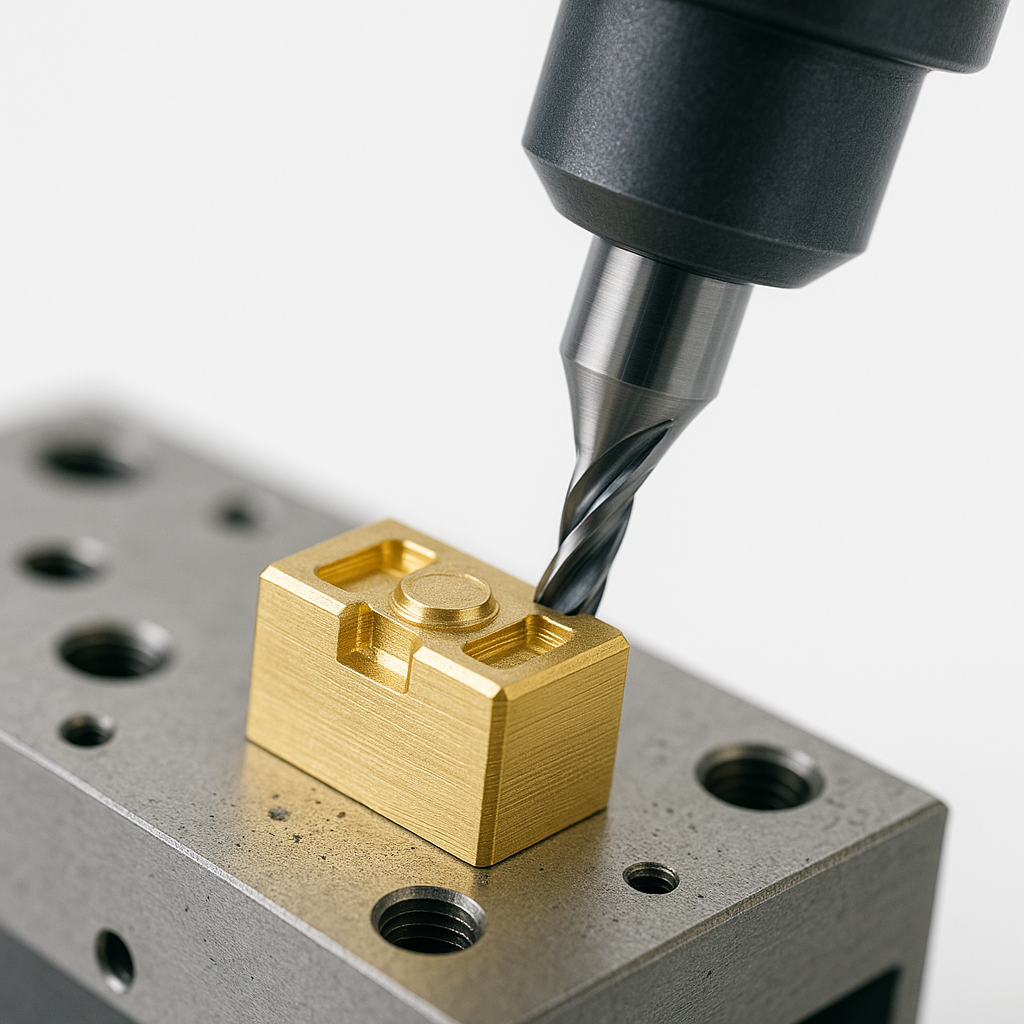

Micro-machining is where manufacturing meets art – carving, drilling, and shaping features smaller than a human hair. In aerospace, medical, and electronics sectors, demand for miniature components continues to rise. Yet maintaining tolerances below a micron in such small geometries has always been a major challenge. That’s where AI micro machining steps in, bringing data-driven control, adaptive optimization, and predictive intelligence to the smallest scale of precision manufacturing.

The Challenge of Micro-Scale Precision

Conventional machining techniques struggle when moving from millimeters to microns. Tool wear, vibration, thermal drift, and even ambient temperature can cause significant deviations when working at miniature scales.

Operators often rely on manual parameter adjustments and experience-based intuition – an approach that’s inconsistent and time-consuming. With tolerances shrinking and materials becoming more complex (like titanium alloys or ceramics used in aerospace and medical implants), even the most skilled machinists face limits.

How AI Enhances Micro-Machining

1. Predictive Parameter Optimization

AI algorithms can analyze spindle load, tool deflection, and cutting forces in real time, automatically adjusting speed, feed, and depth of cut. Instead of fixed settings, the machine continuously optimizes its own parameters for the best possible finish and accuracy.

This adaptive capability reduces tool breakage and rejects while improving repeatability – vital for high-value parts like surgical stents or miniature turbine blades.

2. AI-Based Tool Wear Detection

At the micro scale, tool wear can occur invisibly long before a catastrophic failure. Machine vision and sensor fusion enable AI systems to detect subtle changes in vibration or acoustic signals that indicate wear.

Once detected, the system can either compensate automatically or prompt predictive maintenance before quality deteriorates – extending tool life and uptime.

3. Closed-Loop Feedback for Nanometer Accuracy

AI-powered control systems are now integrated directly into the servo drives of high-end CNC machines. This closed-loop feedback allows for sub-micron correction based on temperature drift, spindle dynamics, or even air pressure.

The result is nanometer-level repeatability, critical for semiconductor and optics applications where dimensional accuracy defines performance.

Applications Across Key Industries

Aerospace

AI micro machining enables the production of ultra-lightweight turbine components and fuel-system parts that reduce overall aircraft weight while maintaining strength and reliability.

Medical Devices

In the medical sector, precision and surface integrity are non-negotiable. AI helps machine complex geometries for implants, dental screws, and surgical tools – ensuring biocompatibility and traceable quality data for every part.

Electronics & Optics

From smartphone components to micro lenses, AI-assisted processes ensure smoother finishes, tighter tolerances, and defect-free production. Automated inspection powered by computer vision identifies even microscopic burrs or cracks.

From Smart Machines to Smart Manufacturing

AI micro machining isn’t just about smarter machines – it’s about connecting every element of production into an intelligent ecosystem. Data from sensors, cameras, and digital twins flows into central manufacturing intelligence platforms.

These systems correlate tool data, environmental variables, and production outcomes across shifts and facilities. Over time, they learn which combinations produce the best results, turning every machining run into an opportunity for continuous improvement.

As companies integrate AI in CNC machining and micro manufacturing lines, they’re also unlocking new possibilities for robotic handling, automated inspection, and software-driven process control – bridging the gap between machining precision and digital manufacturing intelligence.

The Road Ahead: Autonomous Micromachining

The next evolution will be self-correcting, autonomous micro-machining cells that manage their own calibration, maintenance, and production scheduling. Imagine a system that not only adjusts parameters but also predicts when the air spindle needs cleaning or when a laser pulse requires recalibration – all without human intervention.

Manufacturers like Makino, GF Machining Solutions, and Mitsubishi Electric are already developing AI-embedded micro machining platforms that can learn from every cut and adapt instantly. As machine learning models mature, the boundary between physical precision and digital intelligence continues to blur.

Key Takeaways

- AI micro machining achieves sub-micron precision by analyzing and adapting in real time.

- Predictive algorithms improve process stability, reduce tool wear, and optimize throughput.

- Industries from aerospace to medical are seeing transformative gains in accuracy, consistency, and automation.