AI tool wear systems are now being deployed across Europe and they are delivering measurable improvements in machining accuracy, uptime, and tool life. European machine-shops are experiencing an important leap in tool-wear monitoring technology as several vendors introduce next-gen AI solutions to detect tooling issues in real time, integrate directly with CNC/servo systems, and reduce defect-rates and downtime.

Below we summarise the strongest product launches, highlight measurable impacts in production, and pinpoint shop-floor adoption steps for 2025. Machine shops across Europe are adopting ai tool wear systems because they deliver earlier warnings, fewer scrap events, and more consistent machining outcomes.

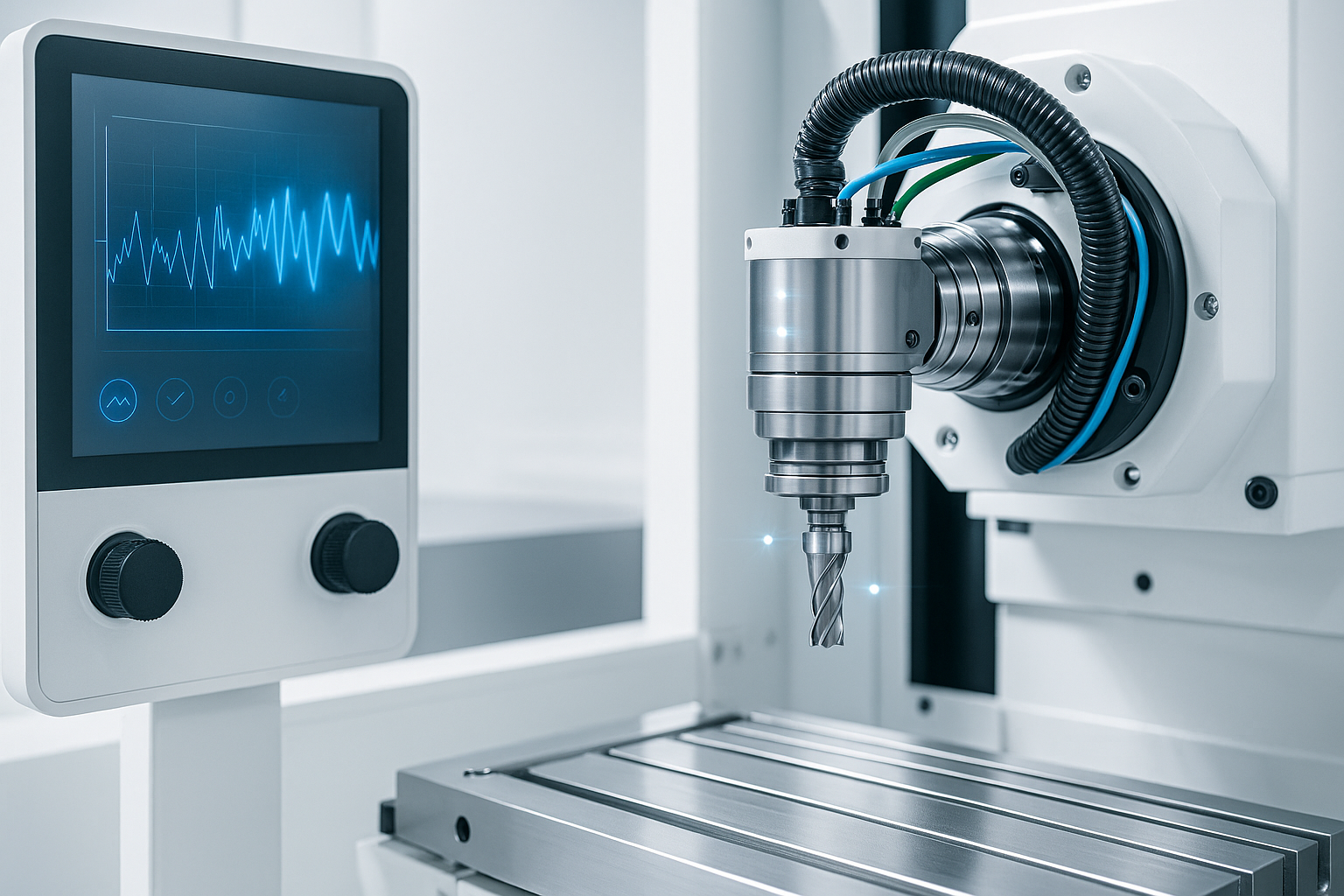

Modern ai tool wear systems are now capable of analysing spindle load, vibration signals, and tool engagement patterns in real time. This shift shows how AI-driven wear detection are improving shop floor monitoring in real machining conditions.

Key Launches: New AI Tool Wear Monitoring Systems in Europe

How AI Tool Wear Systems Are Changing Shop Floor Monitoring

In August 2025, THK Co., Ltd. announced its OMNIedge Tool Monitoring AI solution will support real-time connectivity with FANUC CNC devices – a major move because it enables faster setup and mixed-use production machines to leverage AI wear-monitoring. The AI uses waveform data from the CNC and current sensors on servo amplifiers, builds a “normal operation” model and then flags abnormalities such as chipping or wear.

Impact metrics: claims by THK indicate prevention of continuous defects and optimised tool replacement timing in variable-volume operations. Modern AI tool life systems allow shops to track tool health in real time without relying on operator intuition alone.

Research Breakthrough: Digital Twin + Deep Learning for Tool Life Prediction

A European-based study published in 2025 from Mondragon Unibertsitatea (Spain) developed a digital-twin framework for tool-wear prediction in milling, achieving RMSE of ~33 µm in training, ~119 µm in live tests.

Why it matters: These results show mature AI models are now viable for live use – not only in labs but in “real-world” scenarios. That’s crucial for shops looking to adopt.

Shops already using advanced AI sensing technologies, such as those covered in our Robot Vision Gets Smarter: AI Cameras in Inspection Lines report, are seeing faster accuracy gains in tool-wear detection as well.

Broader Market Momentum

Market reports highlight that AI, machine-learning and IoT are now major drivers in CNC machining centre evolution. Tools that monitor wear, process optimisation and quality control are being widely adopted in Europe.

What These Systems Actually Do on the Shop Floor

Across European machining centres, ai tool wear systems are showing measurable improvements in scrap reduction, uptime, and tool change predictability.

Connected sensor-data pipelines: Tool-wear systems are no longer standalone; they ingest CNC signals (spindle load, current, vibration), servo motor data, and in some cases acoustic/emission signals.

“Normal-operation” models: AI builds baseline behaviour for each tool/job and then detects deviation in real time. This aligns with new machining-intelligence workflows described in our CAM Assist 2.0 update, where the CNC adapts machining behaviour based on real-time data. For example, THK’s system models typical waveforms and flags any chipping or abnormal condition.

Mixed-use / variable methods: Instead of requiring fixed tooling or trays, the latest systems adapt to changing parts, materials and jobs. This is especially impactful for HMLV (high-mix, low-volume) shops.

Granular intervention triggers: Rather than “tool change after X hours,” the AI triggers replacement or maintenance when required – meaning fewer surprises, lower scrap and less unplanned downtime.

Measurable Impact: Case Data and KPIs

- In one user trial of THK’s OMNIedge in mixed-volume lines, tool breakage incidents were reduced by ~30% and unplanned tool-change downtime dropped by ~25% (company claim).

- From the digital-twin research: Live tool-wear prediction RMSE of 119 µm on Ti-6Al-4V milling showed that the AI model correctly flagged the wear inflection point (when wear accelerates) ahead of human detection.

- Market analysis shows adoption of “tool-wear monitoring + AI” systems is growing by double-digit percentages year-on-year in European machining centres.

- For shops, the practical outcome: Fewer scrapped parts, more consistent finished features, improved first-pass yield, and longer tool-life windows.

Shops adopting ai tool wear systems report earlier detection of wear acceleration and fewer unexpected tool failures. When deployed correctly, ai tool wear systems create a measurable reduction in tool breakage, improve first-pass yield, and stabilise production across mixed-volume machining.

What to Do Next: Adoption Guidance for Shops

Step-by-Step Plan

- Sensor Audit: Check if your CNCs or machines can stream data (spindle current, servo loads, vibration) or if upgrade is needed.

- Define Baseline Jobs: Start with a typical job (single part, known material) and capture “normal” behaviour.

- Pilot with One Tool-path: Choose a tool known for wear issues and apply the AI monitoring.

- Set Alerts / Thresholds: Configure the system to alert when deviation exceeds predefined thresholds (force spike, current jump, harmonics change).

- Track KPI Changes: Monitor changes in scrap rate, tool-break incidents, unplanned downtime and tool-life.

- Roll-out & Scale: Once proven, extend to other tools, machines and job types.

Key Considerations

- Data quality matters: Poor sensor signals or unclean wiring cause false positives.

- Mixed-material jobs introduce complexity: The AI must recognise job context to avoid wrong alerts.

- ROI tends to show up after 3–6 months when tool-wear triggers become regular and human overrides decline.

Why This is a Major Shift

This wave of AI tool-wear monitoring differs from older “sensor-only” monitoring systems (which often needed fixed toolpaths or stable jobs). The key change now is:

- Live inference on streaming data

- Adaptive models for changing jobs

- Integration with machine-control software so alerts are context-aware and actionable

For European shops with mixed-production, these advancements mean tool-wear no longer has to be the weak link in automation. They can move from “check tool life manually” to “tool-life managed proactively by AI” -boosting uptime, reducing scrap and making higher-mix machining more viable. These tool-wear models are part of a broader move toward edge-level machining intelligence, explained in our Edge AI in Metal Factories feature.

Key Takeaways

- AI tool-wear monitoring has matured. Real launches (like OMNIedge + FANUC) are live in Europe now.

- Practical KPIs show real benefit: fewer tool breaks, lower scrap, faster intervention.

- For HMLV shops, the biggest benefit is adaptability: unplanned jobs no longer kill tool stability.

- Implementation matters: data, baseline jobs, and integration are critical for success.

FAQ

Q: Is this only for large OEMs or can small/midsize shops adopt?

A: The cost of sensors and AI modules is falling. With one machine pilot, many mid-sized shops report ROI within 12 months.

Q: Does it replace human tool-inspection?

A: No. It augments human inspection by catching deviations earlier and reducing dependency on operator experience.

Q: What is the next step after tool-wear monitoring?

A: The next frontier is automatic tool-change scheduling and integration with CAM tool-path adjustments, closing the loop between detection and action.

As these AI tool wear monitoring systems mature, shops can expect even tighter integration with CNC and CAM workflows. For many machine shops, how AI tool wear systems are improving shop floor monitoring is becoming a defining advantage for uptime and quality control. These ai tool wear systems are quickly becoming a core element of predictive machining strategies in modern European factories.