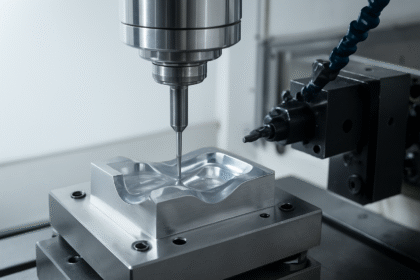

Traditional CAM systems have long depended on human programmers encoding toolpaths, feeds, and speeds based on rules, heuristics, and experience. ...

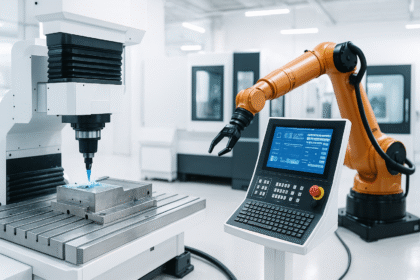

Material transport has always been a hidden bottleneck in metalworking. Sheets, cut parts, and semi-finished assemblies must move continuously between cutting, bending, welding, and finishing....

Machining operations - milling, turning, drilling - often exist in silos: design on one side, shop floor execution on the other. Traditional CAD/CAM workflows lack tight feedback from the real world. ...

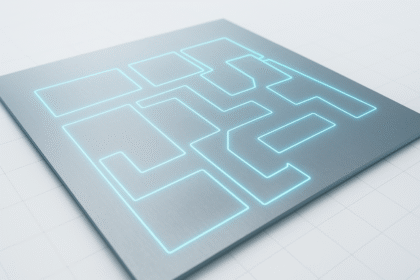

In sheet metal fabrication, profitability often comes down to material efficiency. Every percentage point of scrap reduction translates directly into cost savings, margin protection, and sustainabilit...

In CNC machining, the smallest unplanned stoppage can ripple into days of lost productivity. A spindle bearing failure, a tool breakage, or a motor overheating not only halts production but also derai...

Welcome to our weekly AI + Machine Tools round-up. Each week we scan the global CNC, sheet metal, robotics, and welding sector...

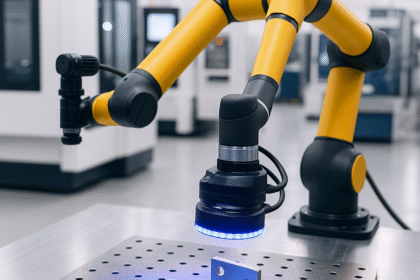

Quality is a competitive edge in fabrication. Missed defects can trigger expensive rework, warranty claims, and brand damage. ...

For metalworking shops, time is the most valuable resource. Every day lost to inefficient scheduling eats into margins, delays deliveries, and erodes customer trust....

Welding has always been a critical stage in sheet metal fabrication. A single defect - a crack, porosity, or incomplete fusion, can compromise an entire assembly...

Artificial intelligence has moved from the margins of manufacturing into the heart of shop floor operations. ...