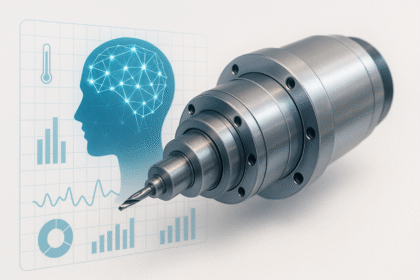

The Core of Every Machine In any CNC or machining centre, the spindle is the beating heart – the component that defines speed, precision, and uptime. When a spindle goes down, production halts, ...

For decades, writing CNC programs meant mastering complex syntax and carefully structuring every line of code. Now, a new shift is unfolding in workshops and digital manufacturing environments worldwi...

The Rise of the Algorithm on the Shop Floor For decades, human experience has been the foundation of CNC programming. From selecting toolpaths to optimizing feeds and speeds, skill and intuition have ...

AI in manufacturing 2025 continues to accelerate. This week’s launches reveal how industrial AI is moving from pilots to daily production - across software, robotics, and compute....

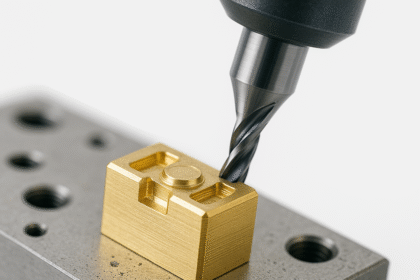

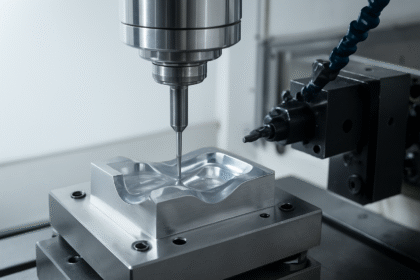

Micro-machining is where manufacturing meets art - carving, drilling, and shaping features smaller than a human hair. In aerospace, medical, and electronics sectors, demand for miniature components co...

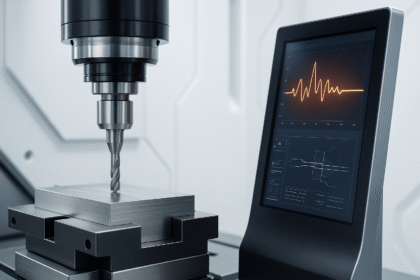

CNC milling is the backbone of precision manufacturing, but even the most advanced machines aren’t immune to chatter – the high-frequency vibration that degrades surface finish, shortens tool li...

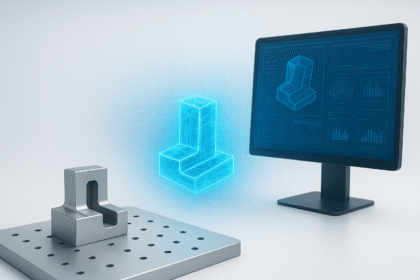

Traditional CAM systems have long depended on human programmers encoding toolpaths, feeds, and speeds based on rules, heuristics, and experience. ...

Machining operations - milling, turning, drilling - often exist in silos: design on one side, shop floor execution on the other. Traditional CAD/CAM workflows lack tight feedback from the real world. ...

In CNC machining, the smallest unplanned stoppage can ripple into days of lost productivity. A spindle bearing failure, a tool breakage, or a motor overheating not only halts production but also derai...

For metalworking shops, time is the most valuable resource. Every day lost to inefficient scheduling eats into margins, delays deliveries, and erodes customer trust....