Coventry, UK – FANUC UK’s Future of Precision Engineering 2026 event is set to bring more than 30 world-leading technology partners together from 27–29 January 2026 at the company’s Ansty Park headquarters, showcasing the latest developments in automation, robotics, CNC machining, injection moulding, digitalisation, sustainability, and AI-driven manufacturing.

The event is structured across three thematic days, each focused on a core challenge facing modern manufacturers: sustainability and efficiency, AI and connectivity, and skills and workforce development. The programme blends expert talks, panel discussions, live demonstrations, and a large exhibition space where industrial technology leaders will present next-generation solutions.

Free to attend, the open house offers manufacturers across plastics processing, CNC machining, and automation a rare opportunity to benchmark emerging technologies and gain insight into where industrial AI is heading next.

Day One: Sustainability Meets Precision

The opening day centres on industrial sustainability and energy efficiency, two pressures that continue to intensify across UK manufacturing. Sessions explore how precision engineering and automation are being used to reduce waste, lower energy consumption, and improve operational resilience without compromising quality.

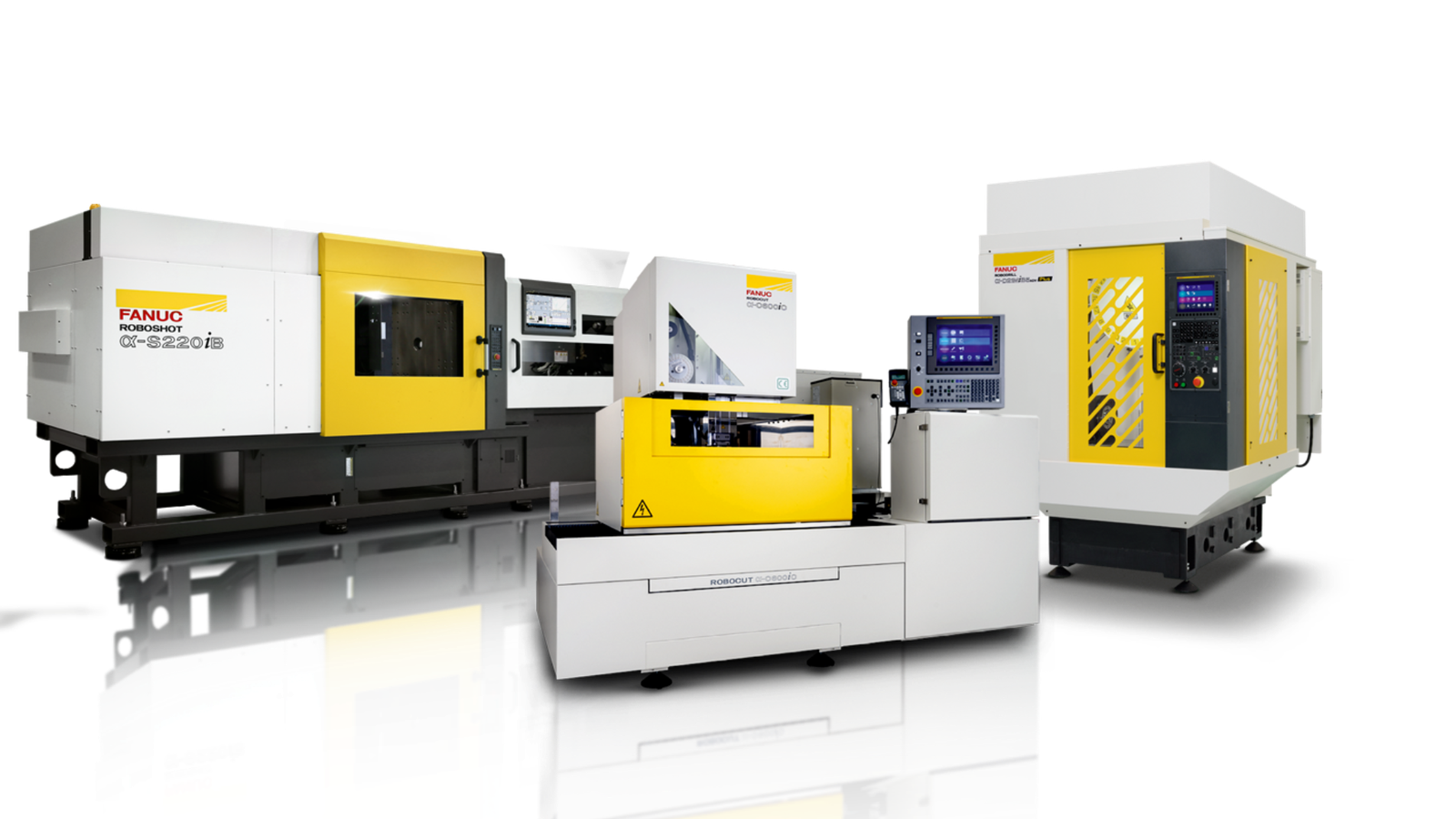

Live demonstrations from FANUC’s CNC and robotics portfolio show how advanced control, connectivity, and automation can increase throughput while supporting sustainability targets. The focus is practical, measurable improvement rather than theoretical ambition.

Day Two: AI and Connectivity – A Catalyst for Competitive Manufacturing

The second day places AI firmly at the centre of the agenda. Dedicated to AI adoption and industrial connectivity, this day frames artificial intelligence as a core enabler of scalable automation and smarter production environments.

A headline panel discussion, AI in Manufacturing: Driving Efficiency, Innovation, and Growth, examines how AI models are reshaping factories. Topics range from predictive quality and process optimisation to real-time data loops that continuously improve performance.

Why AI Matters in Precision Manufacturing

Operational Intelligence

AI is increasingly applied to machine and process data to enable predictive maintenance, faster fault detection, and real-time optimisation on the shop floor.

Quality Automation

Machine learning models can identify subtle patterns in production data, reducing defects, improving consistency, and lowering scrap rates.

Connected Systems

Full integration across CNC machines, robots, sensors, and MES platforms allows AI systems to act on production KPIs holistically rather than in isolation.

Industry analysis: While many manufacturers have trialled standalone AI tools, sustained competitive advantage emerges when AI is embedded into connected workflows that link planning, execution, and continuous improvement. Vendors such as FANUC are moving beyond traditional automation toward industrial-grade AI ecosystems where edge computing, machine connectivity, and cloud-assisted analytics converge. This represents a critical step for manufacturers looking to scale AI impact quickly and safely.

Exhibitor Spotlight: AI-Relevant Players

Several exhibitors are bringing technologies that directly extend AI value across manufacturing environments, including:

- Applied Data Science Partners (ADSP) – Industrial AI and generative model applications

- Kistler Group – High-resolution measurement solutions feeding AI and analytics platforms

- Intouch Monitoring – Real-time shop-floor monitoring enabling AI-driven productivity gains

Alongside these are exhibitors providing the foundational infrastructure required for intelligent manufacturing, including sensor technologies, MES integration tools, and robotics platforms that act as high-quality data sources for machine learning.

MTA perspective: The presence of the Manufacturing Technologies Association (MTA) highlights the sector-wide shift toward AI-augmented manufacturing as a core capability rather than an optional experiment. This reflects wider momentum around digital transformation and workforce upskilling across UK industry.

Day Three: Skills, Training, and Workforce Transformation

The final day focuses on people, skills, and long-term capability building. Sessions address skills shortages, training programmes, and strategies for recruiting and retaining a workforce equipped for Industry 4.0.

This theme reinforces a critical reality for manufacturers: technology adoption delivers value only when supported by capable operators, programmers, and maintenance teams who understand connected and AI-enabled systems.

Who’s Exhibiting? A Full Line-Up of Precision and Automation Innovators

Confirmed exhibitors span machine tools, digital systems, polymers, robotics, tooling, and automation services, including:

Motan Colortronic

Manufacturing Technologies Association (MTA)

Ultrapolymers

Sierra 57 Consult

PlastikCity

Hi-Tech Automation

Blum-Novotest

PiovanGroup

Mold-Masters

Zimmer Group

Kistler Group

Renishaw

Labotek GB

YMT Technologies

Solinatra

Nexus SERVOMIX

TH Plastics

Intouch Monitoring

Aquapurge

Mouldshop Ltd

Gunther UK Ltd

EFI Systems

HASCO

SEBi Group

SMC

Hardie Polymers

Husky Medical Moulds

SCHUNK

SimpaTec

PMMDA (Polymer Machinery Manufacturers & Distributors Association)

This breadth reflects the ecosystem approach required to accelerate modern manufacturing and layer AI-enabled insight across production value chains.

MTN Insight: What This Means for UK Manufacturing

Future of Precision Engineering 2026 goes beyond a traditional open house. It signals where UK manufacturing is heading as digitalisation, data, connectivity, and skills converge.

Key takeaways for industry leaders:

- AI and connectivity are now central to mainstream manufacturing investment decisions

- CNC machines, robotics, and MES platforms must operate as connected systems to unlock full AI value

- Workforce readiness remains a strategic priority alongside technology adoption

Manufacturers attending will gain actionable insight, peer-validated strategies, and a clear view of how AI-enabled precision engineering is shaping competitiveness in 2026 and beyond.

Event Details and Registration

The Future of Precision Engineering 2026

📍 FANUC UK Headquarters, Ansty Park, Coventry

📅 27–29 January 2026

Secure your place:

https://ukopenhouse.fanuc.eu/