Humanoid robots aren’t here to replace your lasers or mills. They’re finally creeping into real factory pilots to handle the fiddly last-10% jobs your cobot cell still dodges: de-nesting sharp parts, lineside kitting, awkward flips at the brake, door-opening and part swaps at the CNC. In short, humanoid robots in manufacturing are moving from hype to practical pilots you can evaluate – without the tradeshow noise.

Why humanoid robots in manufacturing are hot right now

- Big electronics pilot activity in the US: deployments discussed for a new AI-server plant, focusing on cable insertion, object placement and simple assemblies.

- Automotive pilots in Europe: humanoids tested for repetitive moves and QC assistance across two factories.

- New UK industrial player: dual-arm, mobile humanoid platform announced for industrial pilots (not just stage demos).

- Reality check from analysts: there’s still an “autonomy gap” – most deployments are pilots, not fleets. Translation: start small and measure hard ROI.

Where this actually helps in sheet-metal and machining

Think brownfield cells with high mix and constant changeovers. That’s where a generalist, human-compatible robot earns its keep.

- Laser downstream de-nesting and stacking

Pop parts from skeletons (micro-tabs included), kit and stack for the next cell. It’s sharp, awkward, and changes every job – perfect for a robot with hands and vision.

Tip: pair with a simple fixture cart and barcode/QR to route kits. - Press-brake tending and flipping

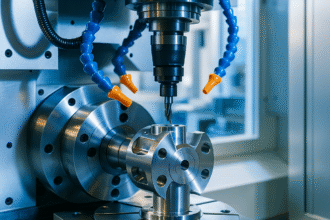

Present blank → gauge → bend → re-orient → rack. Cobots already do this; the humanoid angle is less fixturing and better reuse of human-designed stations (handles, doors, backgauges) when jobs change frequently. - CNC tending plus light rework

Open door, swap parts/soft jaws, wipe chips, label, move to QC. It’s the glue between short runs that keeps spindles turning. - Lineside kitting and replenishment

Tote fetch, kit drop, fixture retrieval and human-style hand-offs where an AMR usually needs a person to finish the job.

When not to bother: long, stable runs where a dedicated gantry/cobot with a simple EOAT is cheaper and faster. If you can standardise, do that first.

Quick comparison

- High-mix, low-volume cells: Humanoid best (reuses human stations, minimal re-fixturing).

- Stable, repeatable runs: Cobot or fixed automation wins on cost and speed.

- De-nesting and kitting: Humanoid strong (dexterity for odd shapes).

- Night-shift coverage: Humanoid covers many small tasks; cobot great for a single station; fixed automation best for one fixed task.

How to run a no-nonsense 90-day pilot (metal-shop checklist)

- Pick one cell, one shift, one metric. Best starter: de-nesting + lineside kitting on night shift.

- Baseline before day 0: throughput/shift, FPY, changeover minutes/job, overtime hours, recordables (injuries), unplanned stops.

- Safety and compliance: risk-assess mixed-mode cells; fence or power-limit; define human/robot zones and e-stops.

- Cycle-time realism: even if slower per part, win back time by cutting waiting, changeover and overtime.

- MTBF and service: uptime targets, on-site response, spares, and hot-swap options.

- Data plumbing: log events to MES/ERP; capture video/sensor data for retraining.

- Exit criteria @ day 90: pass/fail on throughput, FPY, overtime, injuries. If it passes, expand to press-brake tending in the same cell.

Pro tip: keep the pilot scoped to one operator’s universe and write down exactly what the robot does between jobs. The tighter the scope, the cleaner the ROI.

FAQs (fast answers for buyers and plant leads)

Are humanoid robots in manufacturing actually in factories today?

Yes – live pilots exist in electronics and automotive. They’re limited, but real.

Why pick a humanoid over a cobot?

Form factor. In high-mix cells, a humanoid reuses human stations with less custom fixturing. Cobots still win on stable, repeatable runs.

Will it cut metal faster?

No. It’s about handling, tending, and flow. Your laser/CNC still sets the cut/metal-removal speed.

What KPIs should we report upstairs?

Throughput/shift, FPY, scrap/rework, changeover minutes/job, overtime hours, recordables, and MTBF.

Bottom line

If you’ve already squeezed the big wins from nesting, tooling and cycle-time, the next gains are in the messy human bits between machines. That’s where humanoid robots in manufacturing can help-not by being perfect, but by being good enough on night shift, doing the awkward stuff consistently. Start bounded, measure hard, and scale only on proof.