Matta industrial AI is redefining what real time factory intelligence looks like inside everyday manufacturing plants. Matta is not building another vision system. It is building something far more ambitious: factory sentience. This means giving a production line the ability to see its own behaviour, understand what is happening in real time, and improve continuously based on what it learns.

Matta industrial AI is built for real conditions inside factories that run high mix and high volume production.

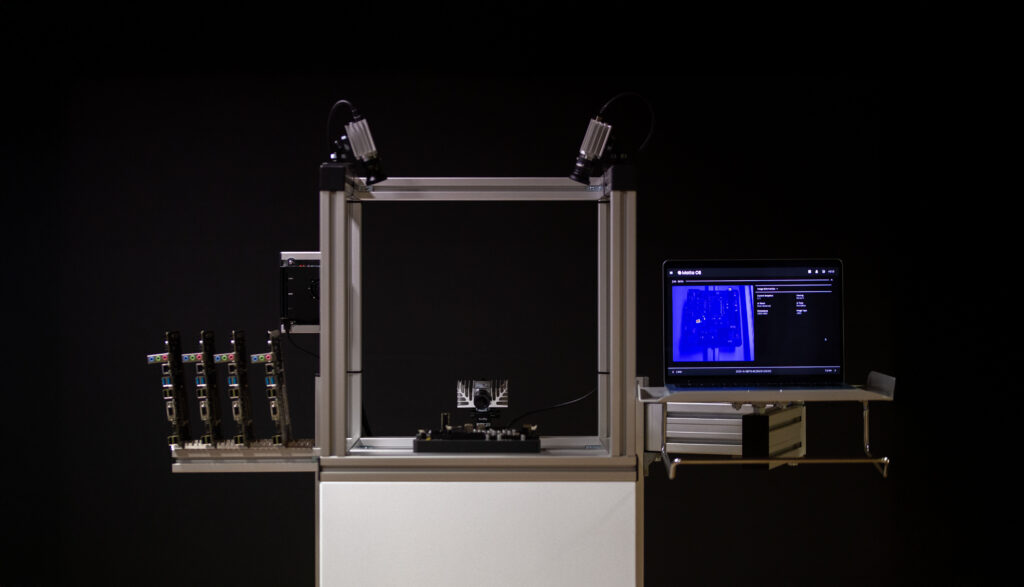

During our visit to Matta’s London office, the team demonstrated a plug and play industrial AI platform that learns a manufacturing line like an apprentice, detects both known and unknown defects automatically, and builds a complete digital history of every part that moves through production. It is built for real factory conditions and is already delivering measurable results in everyday manufacturing environments.

Answer First: What Matta Actually Solves

Matta provides a unified industrial AI system that brings together:

- AI inspection and anomaly detection

- Measurement and verification

- Part level traceability

- Live visibility across production

- Cycle time, flow and bottleneck analytics

- Root cause insights

The platform installs quickly and then begins learning from real production images. It does not need custom lighting, complex jigging, or large datasets. Once the system understands what good parts look like in the real world, it begins inspecting automatically with very high accuracy. This is the core strength of Matta industrial AI because it adapts to production changes without constant tweaking.

For factories wrestling with scrap, rework, drift or unpredictable quality, this is a very practical solution.

The core of Matta industrial AI is the ability to learn real production behaviour rather than relying on code or fixed rules.

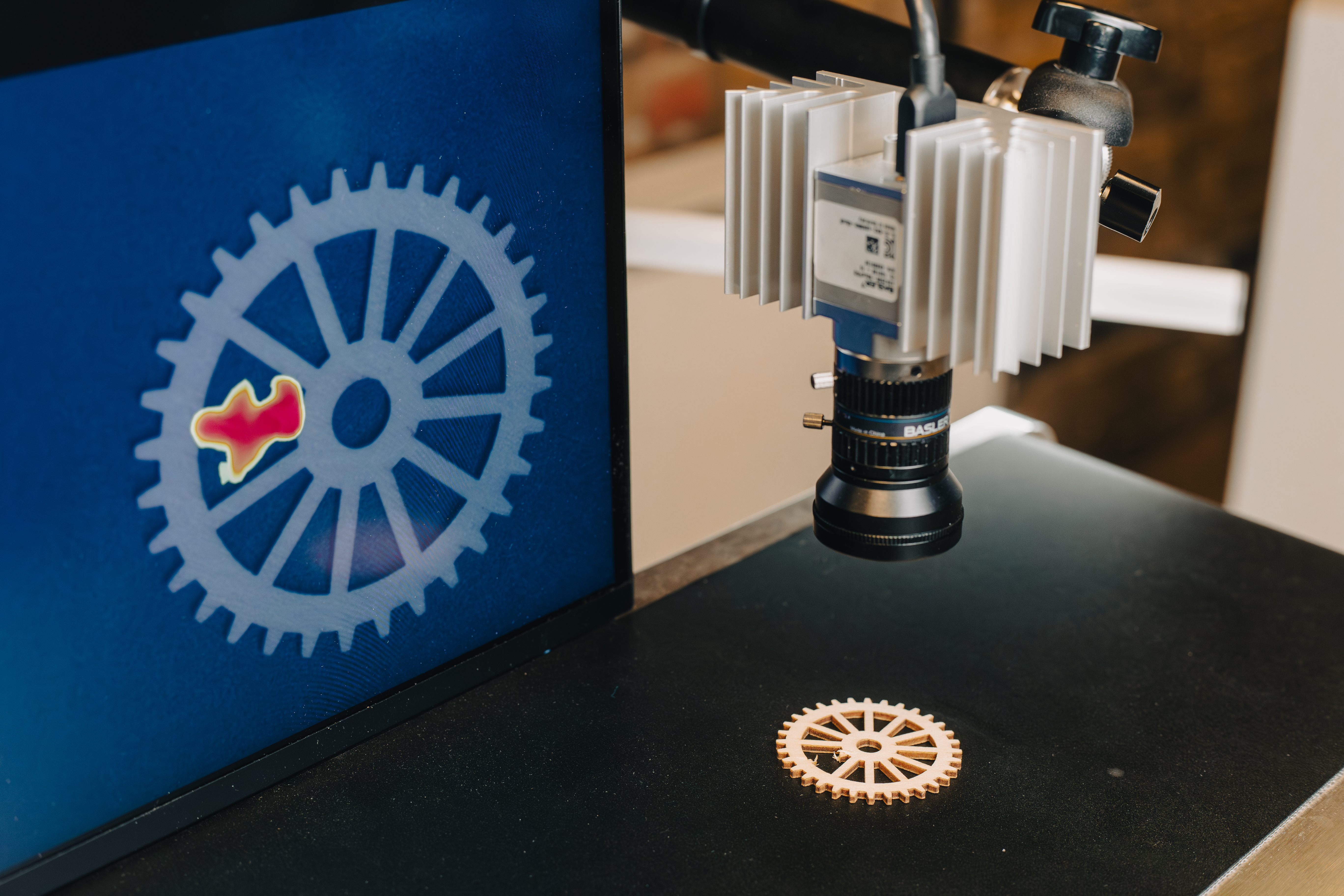

Blue: The AI That Learns the Line

Matta’s inspection system, called Blue, is designed for real industrial variation. It is not dependent on perfect conditions or rigid installations. This learning based approach is what allows Matta industrial AI to detect subtle and previously unseen issues in real time.

During the live demonstration we saw Blue:

- Learn the line from real product flow

- Detect subtle defects that operators were previously missing

- Handle movement, vibration and natural factory lighting

- Identify multiple issues in a single frame

- Capture barcodes and serials to link every image to a specific part

The system can run fully unsupervised or can incorporate expert feedback from operators. That feedback becomes part of the model and helps the AI capture decades of on the job knowledge.

MattaOS: A Live Window Into the Factory

MattaOS is the digital layer that brings everything together. It provides a single view where teams can:

- Monitor QC from any device

- Track parts across stations

- View cycle times and bottlenecks in real time

- Access images and data for every part

- Review defects and trends

- Strengthen the AI using human-in-the-loop review

By combining inspection, tracking and analytics in one place, Matta industrial AI gives factories a single source of truth across the entire line. In our briefing, MattaOS displayed a complete digital route card that showed exactly where a part had been, what was checked, what passed, and what failed. By linking every image and measurement to a live production timeline, Matta industrial AI creates a full digital memory of the factory. This is normally spread across multiple systems in most factories. Here, it was all in one place.

A Plug and Play Deployment Model

Matta’s installation philosophy might be its biggest differentiator. The company aims to eliminate long deployments and complex integration work.

A typical setup works like this:

1. Install

Compact cameras are mounted in minutes with minimal disruption.

2. Learn

The AI observes real production and builds its understanding of what good looks like.

3. Automate

Inspection, measurement and part tracking switch on automatically.

Most factories see value in weeks instead of quarters. This speed is helping Matta grow across industries including textiles, consumer goods, mechanical components, plastics, metals, electronics and more.

Beyond Inspection: Predicting and Preventing Issues

Matta is now moving into the next phase of industrial AI: correction. The company is developing models that can:

- Predict the root cause behind a defect

- Explain why it happened

- Suggest corrective actions

- Integrate with machines for automated adjustments

This sets the path for future closed loop control where machines can optimise their own behaviour in real time. The long term vision for Matta industrial AI includes real time correction that helps machines adjust parameters automatically.

For machine level applications, see our feature on AI machining assistants.

Capturing and Scaling Operator Knowledge

Every factory has a veteran operator who can detect issues instinctively. They know when a surface finish is drifting or when a machine is behaving differently even if the numbers look fine. Matta’s goal is to take this kind of intuition and scale it across every shift and every station.

The AI is not there to replace people. It is there to capture what they know and make it available across the entire operation.

Why This Matters for the Future of Manufacturing

The factories that win in the next decade will be those that combine human expertise with real time intelligence. Matta’s platform shows what this looks like in practice: a system running directly on the line, learning constantly, and giving operators and managers the visibility they have never had before.

This is a step toward manufacturing environments that can understand themselves, adapt to new materials and processes, and solve problems before they reach a customer.

For broader context, see our regular industry roundup, This Week in AI for Machine Tools

This level of real time visibility shows why Matta industrial AI is becoming a preferred option for manufacturers that need faster, more consistent quality control.

Key Takeaways

- Matta is building factory sentience powered by real time AI

- Deployments take hours and deliver value in weeks

- Blue learns directly from real production and detects subtle issues

- MattaOS provides live part tracking, traceability and factory level visibility

- Next step is AI driven correction and future closed loop control

- The long term goal is factories that improve themselves continuously

FAQ (AEO Section)

What industries can Matta be used in

Metals, plastics, textiles, electronics, automotive, aerospace, food and drink, machinery and many others.

Does Matta replace human inspectors

No. It captures and scales human expertise so quality becomes consistent across shifts and across sites.

Can it work in variable lighting or non ideal conditions

Yes. The AI is designed to handle natural factory variation including lighting changes, vibration and movement.

How fast does it deliver results

Installation takes hours and automated inspection usually begins within days. Many factories see improvements within the first month.

Is it only for defect detection

No. The platform also handles measurement, traceability, bottleneck analysis and root cause insights.

For wider context on industrial AI deployment across manufacturing, see reports from:

McKinsey Industrial AI Overview

MachineToolNews.ai on LinkedIn

One Comment