Innovations in Sheet Metal Processing for 2025

The sheet metal processing industry is undergoing significant changes driven by technological advancements. As machine shops face increasing competition, understanding these trends is essential for maintaining efficiency and meeting customer demands. The integration of automation, artificial intelligence (AI), and sustainable practices is reshaping the landscape, making it imperative for manufacturers to adapt swiftly.

Why This Topic Matters for Machine Shops

The sheet metal processing sector is experiencing a paradigm shift due to factors such as the need for enhanced efficiency, a shortage of skilled labour, and a growing focus on sustainability. These trends are not optional; they are vital for survival in a competitive market. Companies that neglect to invest in these advancements risk falling behind as the industry moves towards more high-tech and automated solutions.

How It Works

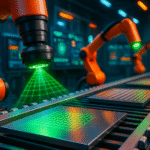

Current trends in sheet metal processing include automation, robotics, digitalisation, and AI. Automation streamlines production by integrating various steps, such as laser cutting and bending, into cohesive systems. Robotics enhances productivity by taking over repetitive tasks, while digitalisation connects machines for real-time monitoring and control. AI optimises processes and ensures quality through predictive maintenance and intelligent control systems.

Practical CNC Applications

Machine shops can implement these trends in various ways. Automated production cells can handle multiple processes, reducing downtime and increasing throughput. Robotics can assist in tasks like welding and material handling, improving consistency and speed. Digital platforms enable manufacturers to configure and order components online, enhancing flexibility and reducing lead times. Additionally, hybrid manufacturing techniques, which combine traditional methods with 3D printing, allow for innovative designs and rapid prototyping.

Benefits & ROI

Investing in these advancements can yield significant returns. Automation and robotics can drastically reduce downtime and scrap rates, leading to improved tool life and overall efficiency. The integration of AI can enhance product quality and reduce waste, further contributing to cost savings. By embracing these technologies, machine shops can strengthen their market position, reduce operational risks, and achieve greater productivity.

Getting Started

To effectively implement these trends, machine shops should consider the following checklist:

- Sensors: Invest in IoT devices to monitor production processes in real time.

- Data Management: Establish systems for collecting and analysing data to inform decision-making.

- Skills Development: Train employees in new technologies and processes to ensure a smooth transition.

- Software Solutions: Utilise digital platforms for procurement and production management to enhance efficiency.

Risks & Limitations

While the benefits are substantial, there are risks associated with these advancements. Data gaps can lead to inaccurate insights, while false alarms from monitoring systems may disrupt operations. Additionally, reliance on specific technologies can result in vendor lock-in, limiting flexibility. Companies must weigh these risks against the potential rewards and develop strategies to mitigate them.

Outlook for 2025+

Looking ahead, trends in sheet metal processing are expected to continue evolving. The integration of AI and hybrid manufacturing processes will likely become more prevalent, enabling even greater efficiency and innovation. As sustainability remains a key focus, companies will need to adopt practices that minimise environmental impact while maintaining competitiveness. The future of sheet metal processing promises to be dynamic, with opportunities for those willing to embrace change.

Key Takeaways

- Sheet metal processing is increasingly driven by automation, AI, and sustainability.

- Companies must adapt to remain competitive in a rapidly evolving market.

- Implementing advanced technologies can lead to significant efficiency gains and cost savings.

- A strategic approach to data management and employee training is essential for successful integration.

- Awareness of potential risks is crucial for maximising the benefits of new technologies.

FAQ

- What are the main trends in sheet metal processing?

- The main trends include automation, robotics, digitalisation, and the use of artificial intelligence.

- How can machine shops benefit from these trends?

- Machine shops can achieve increased efficiency, reduced downtime, and improved product quality through these advancements.

- What should companies consider when implementing new technologies?

- Companies should focus on data management, employee training, and the potential risks associated with new technologies.

Original reporting/source: