Automation has long been the backbone of manufacturing efficiency – but even the smartest robots have limits when they’re rigidly programmed to perform one task in one place. The next wave of innovation, swarm robotics, is reshaping how parts move through smart factories. Inspired by the collective behaviour of ants and bees, these decentralized robotic systems are making production lines more adaptive, resilient, and cost-effective.

What Is Swarm Robotics?

Swarm robotics refers to the coordination of multiple small robots that work collaboratively toward a shared goal. Instead of relying on a central control system, each robot in the swarm operates independently but communicates with others to adjust its actions in real time.

In manufacturing, that means swarms of mobile robots can dynamically share tasks – whether transporting components between machines, sorting parts, or adapting to changes in production flow. If one unit fails, others automatically adjust, keeping material movement seamless.

This decentralised intelligence is what separates swarm robotics from traditional automation. It’s not about one large, expensive robot – but hundreds of affordable, cooperative ones that can collectively handle complex logistics with minimal supervision.

Decentralisation: The Key to Resilience

Centralised robotic systems are powerful but vulnerable. A single failure in a PLC, control unit, or robotic arm can disrupt an entire production line. Swarm robotics flips that model.

Each robot in a swarm acts as both an autonomous unit and a node in a distributed network. Tasks like part transfer, bin sorting, or machine loading can be dynamically reassigned between units. The system self-organises based on live conditions – such as machine status, queue length, or floor congestion.

That resilience is particularly valuable in high-mix, low-volume manufacturing, where part types and routing frequently change. Instead of reprogramming conveyors or AGVs, the swarm adapts instantly to new product data or process updates.

Cutting Bottlenecks and Labour Costs

Material handling remains one of the biggest hidden costs in manufacturing. Manual transport of components – whether by forklift or operator – creates inefficiencies, safety risks, and bottlenecks between production cells.

Swarm robotics systems address this by providing autonomous, on-demand material flow. They can:

- Identify when a machine needs input or collection.

- Communicate with digital twins or MES systems to plan routes.

- Optimise paths to avoid collisions or idle time.

- Scale up or down automatically depending on shift patterns or workload.

The result: smoother throughput, less unplanned downtime, and fewer human touchpoints. Early adopters report throughput gains of 20–30% and ROI within 18–24 months, particularly when integrated with existing AI scheduling and predictive maintenance platforms.

AI + Swarm Robotics: The Real Power Duo

The real value emerges when swarm robotics is integrated into broader AI-driven factory ecosystems.

Machine learning algorithms can analyse production data to determine optimal swarm behaviours – when to prioritise certain machines, reroute traffic, or form temporary clusters for large tasks.

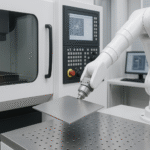

For example, when a CNC machine signals completion via the MES, nearby robots can automatically coordinate to retrieve parts, clean the workspace, and deliver them to inspection – all without central direction. Each interaction refines the swarm’s collective intelligence.

Swarm robotics also complements AI vision systems, enabling robots to identify parts, detect orientation, and handle variation autonomously. Together, they form a closed feedback loop that continually optimises shopfloor efficiency.

Industrial Applications Emerging Now

Swarm robotics isn’t just theoretical – it’s already being piloted in several industries:

- Automotive: coordinating fleets of small robots for intra-plant logistics.

- Electronics: flexible component handling in modular cleanroom environments.

- Metal fabrication: decentralised transport of sheet-metal blanks, fixtures, and finished parts.

- Warehousing: autonomous mobile robots (AMRs) operating as dynamic picking teams.

Companies like ABB, KUKA, and Boston Dynamics are experimenting with modular swarm-capable platforms that connect via standard industrial protocols. Meanwhile, research groups at Fraunhofer IPA and ETH Zurich are advancing the algorithms that underpin collective decision-making and obstacle avoidance.

For manufacturers adopting Industry 4.0, swarm robotics is emerging as the “missing link” between flexible production and real-time logistics.

What Comes Next: From Pilot to Production

The next challenge for manufacturers is standardisation. Swarm systems require common interfaces to communicate with MES, ERP, and AI systems. The rise of OPC UA and MQTT protocols is already simplifying this integration.

In the next 3–5 years, expect to see swarm robotics move from experimental pilots to production deployments – particularly in factories producing high-mix, medium-volume components where flexibility outweighs raw throughput.

Swarm robotics isn’t replacing industrial robots; it’s augmenting them. The future factory will likely combine both – precision robotic cells at the core, surrounded by agile swarms coordinating the flow of parts, data, and value.